How Trenchless Sewer Line Can Save Time and Money

By Mike Kynett, PE

Many communities have aging underground utilities, specifically water distribution and sewer collection piping, that have been in place beyond their intended service life. These utilities are at risk of failure which could result in costly repairs and service outages.

If your community is headed down this path, you may want to learn more about trenchless sewer lining as a quicker-than-normal and cost-effective way to repair your existing infrastructure.

Excavation is Expensive

Budgeting to replace these utilities can be challenging as full replacement options include open-cut trenching and costly street surface restoration. Communities simply do not have the resources to keep up with replacing these utilities throughout their systems.

Sanitary sewer mains can be especially expensive to replace as they are usually deeper than other utilities to account for basement depth service lines. Bypass pumping is also typically needed during the replacement duration to allow for continued service throughout the replacement.

The Trenchless Sewer Line Solution

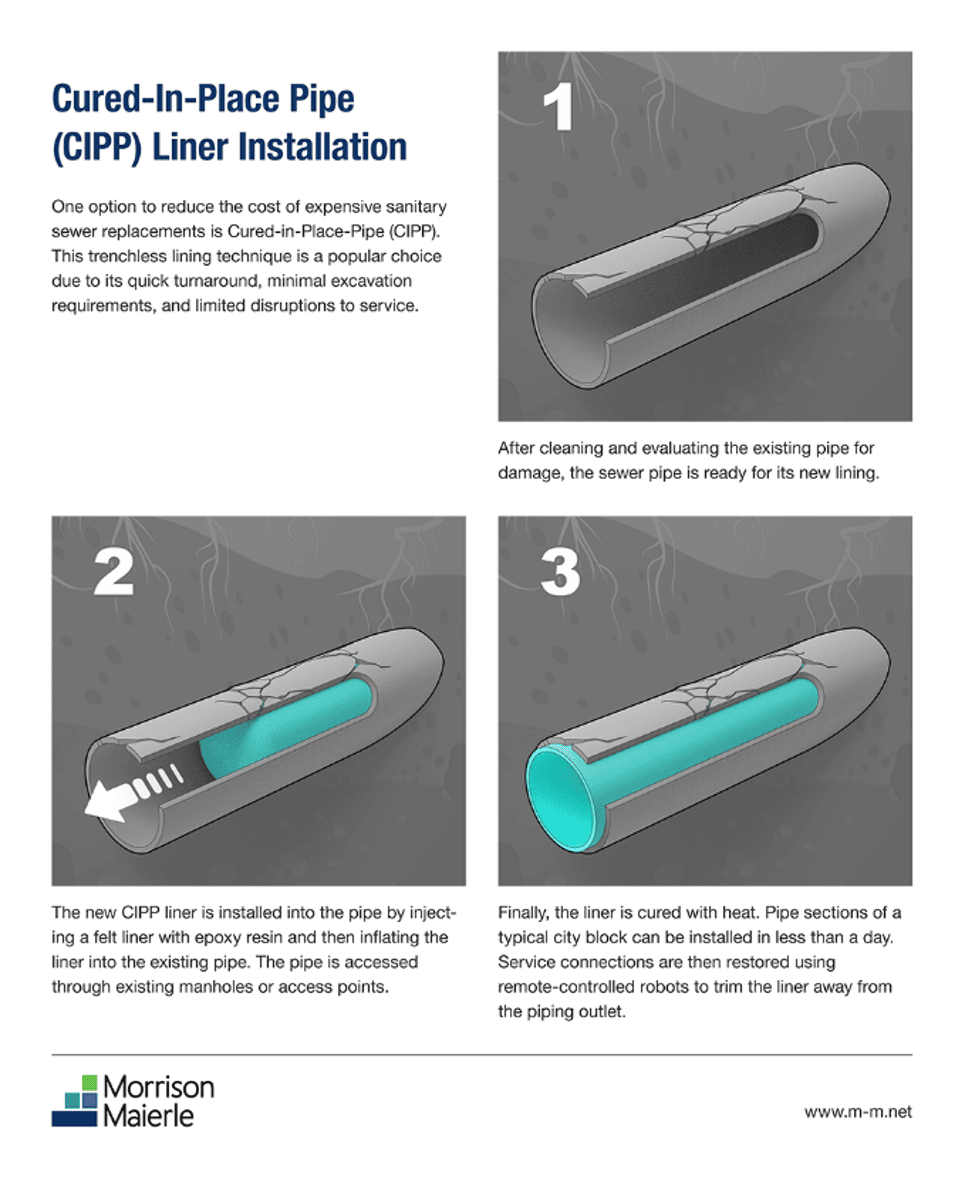

One option to reduce replacement costs is trenchless sewer lining. This method involves installing a new liner inside the existing sewer pipe, and accessing the existing pipe through manholes or other access points, thus greatly minimizing excavation. Specifying the correct product and installation methods results in a new pipe and does not rely on the existing pipe for structural integrity.

There are several lining options, but Cured-In-Place-Pipe (CIPP) is popular. CIPP involves impregnating a felt liner with epoxy resin, inflating the liner into the existing pipe, and then curing it using a heating method. Pipe sections of a typical city block can be installed in less than a day, minimizing any bypass pumping required and eliminating most service disruptions. Service connections are restored with robotic machines inside the new liner using a remote control to remove the liner material from the service piping outlet.

Trenchless sewer lining costs approximately 60-70% of the cost of open-cut replacement methods and takes roughly a third of the time to install. Existing piping must still retain reasonable structural integrity and exhibit minimum flaws. Due to this, areas with existing pipe flaws, such as broken or crushed pipe, may need to be excavated and repaired before lining.

Since the new lining matches the existing pipe, sections of pipe with flat or reverse grade would also need to be excavated before the lining and repaired to obtain proper grades.

Learn More

If you want to learn more about trenchless sewer lining, please contact Mike Kynett at 406-454-5104 or email mkynett@m-m.net.