Cross-Laminated Timber: Clear Considerations for the Entire Design Team

By Chandra McCarthy, PE

Mmmm. Smell that? That lovely, earthy wood smell? All that timber…

Okay, so maybe your nose can’t actually smell the fresh lumber scent as you walk through a new building with abundant timber, but your eyes sure can see it. Furthermore, the sensory appeal of mass timber is only one of its many favorable attributes. It’s no wonder mass timber in general, and cross-laminated timber in particular, are rapidly gaining popularity.

While some mass timber products closely resemble their steel and concrete cousins in both form and function, this isn’t necessarily the case for cross-laminated timber (CLT). CLT and similar panelized wood products are unique in application compared to traditional framing techniques and require design strategy adaptations from the entire project team. When considering mass timber, specifically CLT, for your next project, here are some tips that your entire design team should consider to make it a success.

1. Cross-Laminated Timber panels are custom-made and require design input from the entire project team

CLT panels are formidably large pieces of pressed lumber and glue that are custom-made for your project, so you really need to know what you want before you place an order at the factory. This may require intensive upfront design, as mechanical, electrical, plumbing, fire protection, and information and communications technology systems all need to be adapted for installation in a CLT structure.

According to CLT production engineers, field modification of a 3-ply panel (just over four inches thick) is viable if a bit awkward. For 5-ply panels and thicker, it becomes dramatically more difficult to cut a clean opening in the wood.

Fortunately, CLT manufacturers can do this cutting for you in the factory to ensure a clean finish as an additional service. For ease of assembly in the field, factory machining should be considered for any penetration larger than about 2” in diameter. You will also avoid stray Sawzall cut lines or drill holes if you leave them to the factory.

A major downside of asking the factory to machine your panels is that once a hole is created, there is no patching it. Put another way; there can be no design deviations during construction.

Thus, coordination of your entire building during design is crucial. All disciplines must work together closely to ensure the paper design will indeed work in the field and that critical areas and penetrations are thoroughly coordinated and documented.

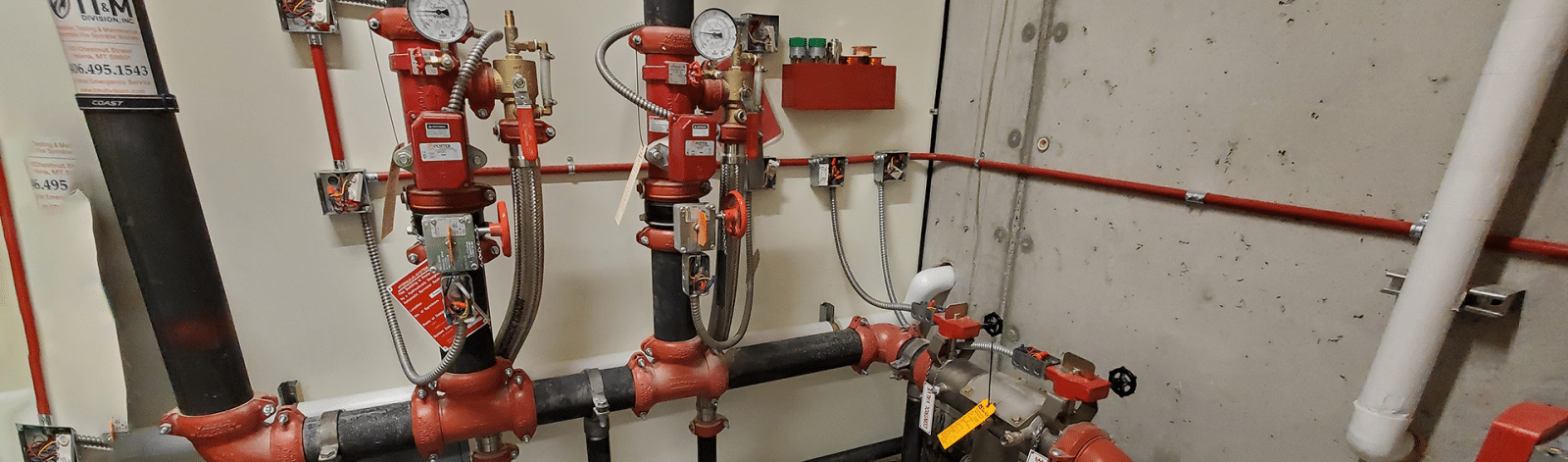

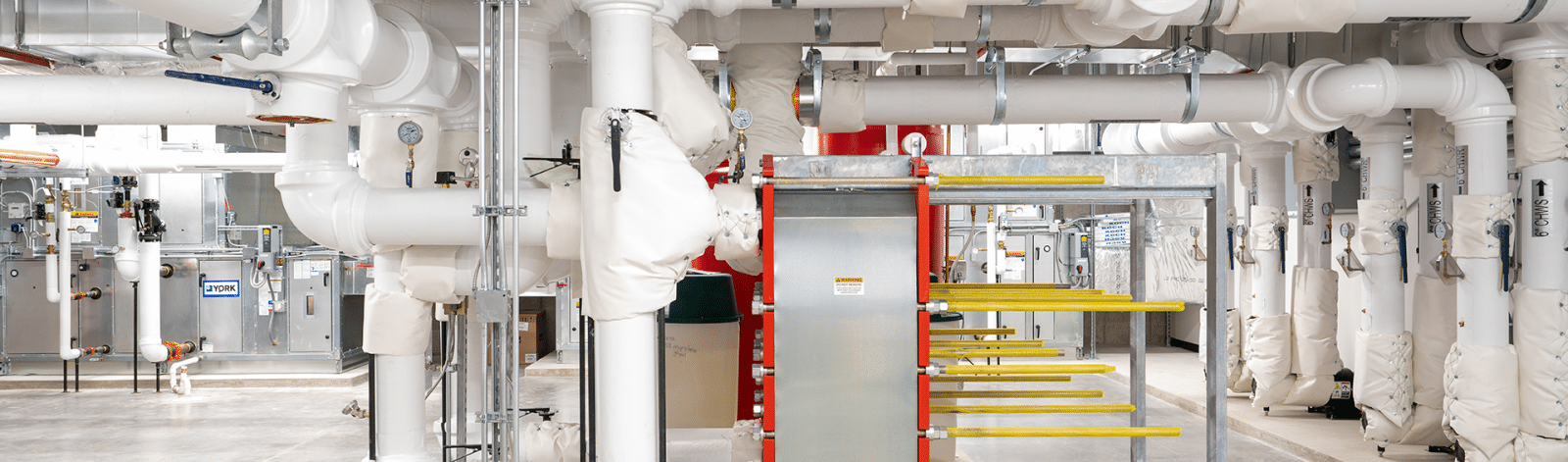

2. CLT makes it more challenging to hide “unsightly” building components like ductwork and pipes

While some people may appreciate the visual interest added by showcasing exposed pipes, conduits, and ducts within a space, others have nightmares about such installations. To avoid inducing nightmares in the latter crowd, mechanical, electrical, fire protection, and information and communications technology designers invest a lot of time carefully hiding/concealing their designs. Often, this means running pipes, conduits, and ducts within framed walls or above dropped ceilings.

With solid CLT wall or roof panels, traditional concealed cavities for these building components are lost. But before you eliminate modern amenities like heating, plumbing, or electricity from your project for fear that there’s nowhere to run any of it, consider the following options:

- Intentionally style spaces around the look of exposed ductwork.

I know. We just addressed that the word “exposed” can induce nightmares. But can exposed installations get a bad rap because of poor execution? A thoughtful exposed ductwork design could mean the difference between detracting from space and contributing to it. Perhaps industrial/rustic chic is exactly the look you are going for? Or, consider dressing up exposed ductwork with a complementary paint color or architecturally styled air terminals. - Embrace surface mounted conduit for light fixtures and other electrical needs.

If “exposed ductwork” made you pucker, there is a good chance that “surface-mounted conduit” has a similar effect. However, a CLT conscientious electrical engineer can work with you to lay out clean runs of the exposed conduit where necessary. They will make the design look intentional and not leave it to chance whether a tangled web of metal tubes is strewn across your beautiful wood. - Consider routing conduit through the insulation in exterior walls.

Poking conduit through CLT panels and letting it reside within an insulation layer can be a great option to get power where you need it while concealing conduit runs. Remember that this only works for conduit, though, and not pipes (which are susceptible to freezing). - Incorporate spacious chases in strategic locations to facilitate piping, ductwork, and conduit.

Chases can hide whatever it is you don’t want to see. Open communication between all design team members is key when it comes to creating smart chases that look good and serve their purpose well. - Furr out walls and add soffits to allow for more traditional routing where you need it.

Sometimes you just need to add the extra wall thickness to achieve the desired final product. That works, too! But just as with chases, you will want frequent dialogue amongst team members to determine the most effective wall furring approach.

Our full design team is eager to help you make every aspect of your CLT project successful! Ready to start planning?

Contact us here.