How to Design Buildings That Are Easy to Maintain

Maintenance is sometimes overlooked by building design teams. Here's how to avoid that problem

How do you design buildings that are easy to maintain? In addition to creating projects that are permittable and constructible, many know this is one of the many considerations building design teams think about at the beginning of a project. However, maintenance is one area that sometimes gets overlooked. One way to avoid this is to adopt the three-legged stool model early in your design discussions to avoid unexpected expenses to perform simple maintenance tasks.

What’s the Three-Legged Stool Model for Building Design?

When we talk about the three-legged stool approach to design, all projects must be equally:

- Permittable – All designs must meet this minimum level from the Authority Having Jurisdiction (AHJ) to receive a permit to build.

- Constructible – Various design aspects are challenging to build, which is relatively common.

- Maintainable – Ensure you have a design that locates equipment that is easy to access and where there is clear ingress and egress from the building when equipment needs to be replaced.

Like a three-legged stool, if one of these legs fails and attention is not given to all three areas of design, building projects may come up short, resulting in a finished product that is hard to maintain.

Three ways to ensure a building is easy to maintain

The design industry has been moving towards more energy-efficient designs for years, and system design and equipment efficiency have improved measurably. Additionally, many projects see some form of post-construction commissioning to ensure that all systems operate as they were designed.

However, that only ensures design compliance when the project is handed over to the owner. All equipment needs to be maintained, and if maintenance is difficult or sometimes impossible due to equipment placement or building constraints, then maintenance will likely get deferred or not happen at all. If equipment is not maintained correctly, it will become less efficient, cost more to operate, and eventually fail.

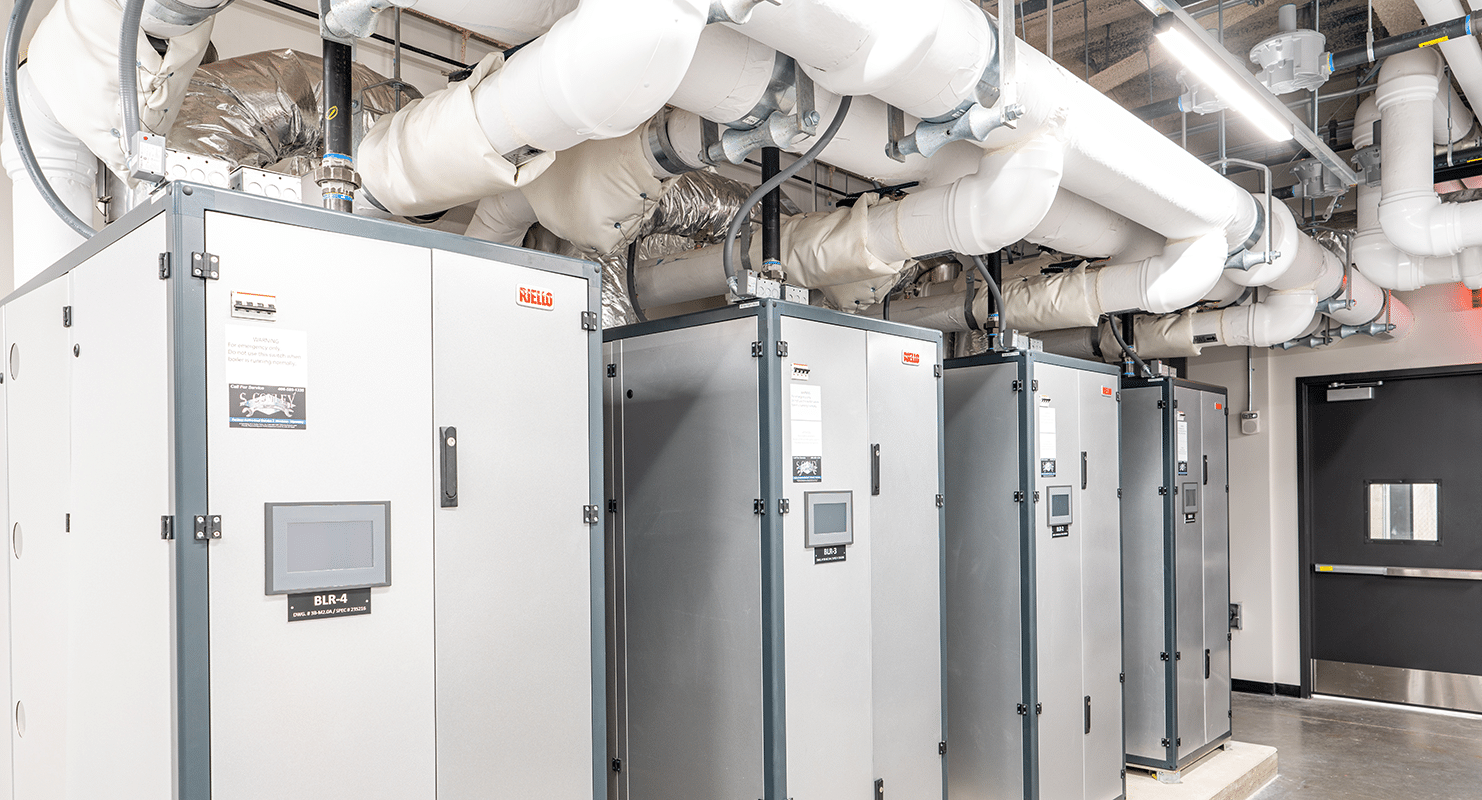

For example, a building is generally assumed to last at least 50 years, whereas an HVAC (Heating, Ventilation, Air Conditioning) system might only last 15 years. If there isn’t an easy way to remove and replace HVAC components from the building at the end of their useful life, the tendency will be to keep using them as they become less efficient until they eventually fail. When this happens, the building owner will have difficulty replacing the system, which will cost them time and money. And when it comes down to it, the more significant inconvenience is the unpredictability and the possibility of your building being unusable should it happen at the wrong time of year.

To avoid things like this, design teams have several approaches they can take, such as:

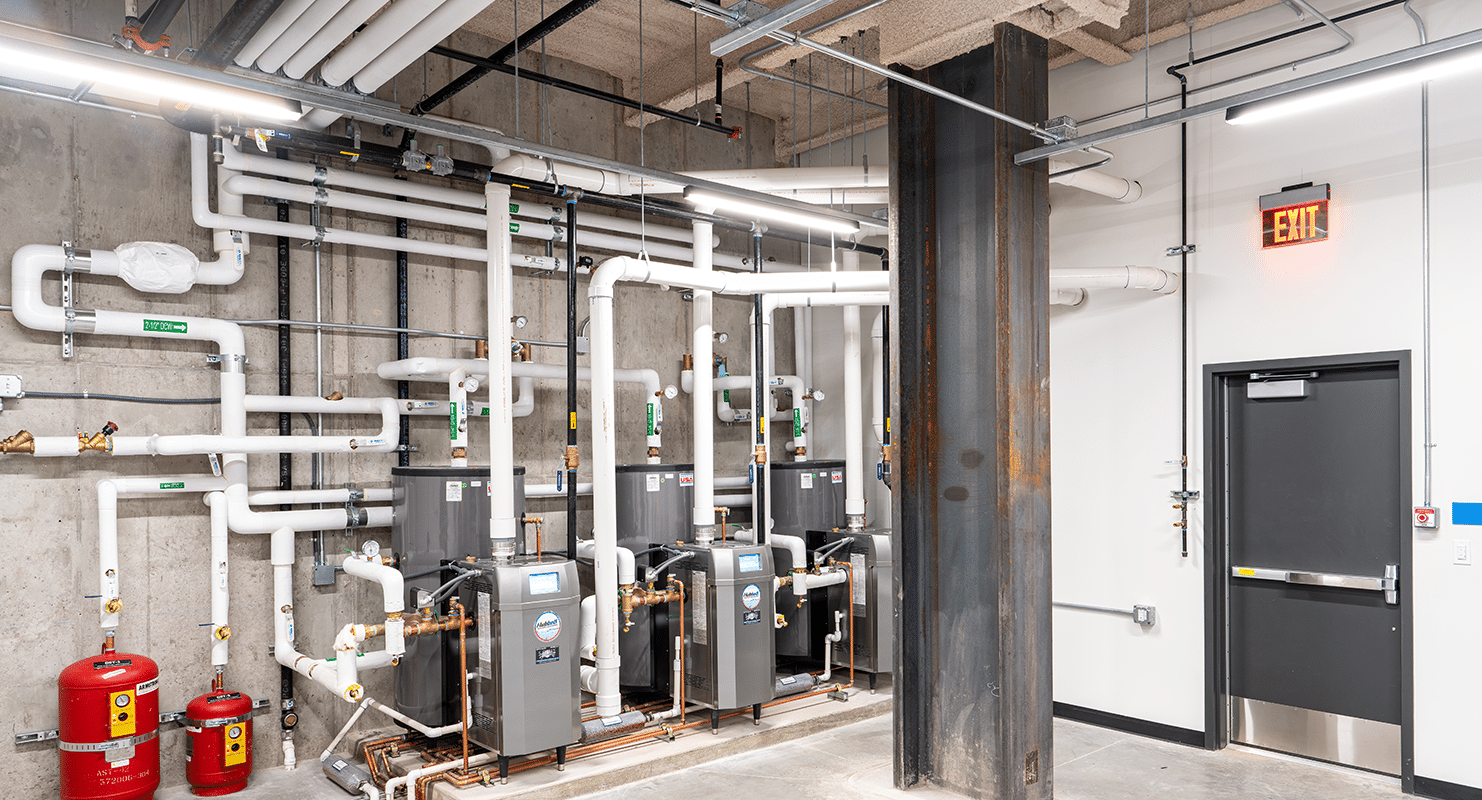

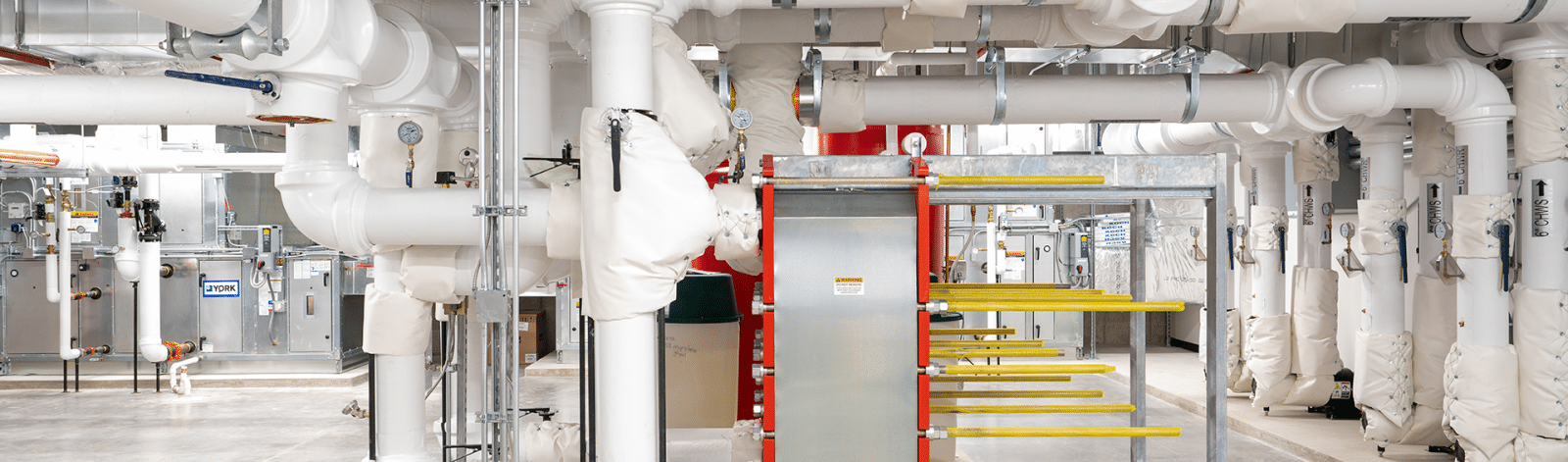

- Working with the building designer early in the design process to ensure all equipment can be easily removed from the building for replacement. That could be as straightforward as installing double doors in the equipment room and the building exterior. One of the best ways to ensure maintenance issues are addressed is to coordinate with the design team and the owner early and often.

- When laying out equipment rooms, locate items that need regular and frequent maintenance close to entry doors. Also, make sure heavy items can be removed easily. For example, a 20 HP electric motor weighs about 640 pounds. Ensure a floor path to the building exit is clear of low-level piping, conduit, or other obstacles that could impede a heavily moving dolly. If equipment is mounted on the roof, ensure an access door or hatch is large enough to bring in components that need replacing or a clear path to the ground for a crane.

- Discussing outcomes with the maintenance crew during the design phase. Ask them what they need to maintain, how often they need to access hard-to-reach spaces, and what they see as obstacles. A clear picture of potential challenges will help design teams deliver a project that meets or exceeds an owner’s expectations.

As building designers and owners know, like the Missoula Airport management and staff, without ways to easily access equipment and perform updates addressed early in the design phase, there’s a risk of creating a potentially complex and expensive facility to maintain.

That’s why at Morrison-Maierle, we use the three-legged stool model for building design, a tried-and-true approach to excellent project outcomes.

If you have questions or want to know more about our company, projects, and approach, contact us.

Sign up to receive our newsletter to learn more about our company and approach to projects