NFPA 820

The “Standard for Fire Protection in Wastewater Treatment and Collection Facilities,” otherwise known as NFPA 820, is a standard that describes fire protection methods for different types of wastewater and collection facilities. The methods of protection for facilities should follow NFPA 820 unless federal, state, or local laws and regulations require other methods. (More information on NFPA 820 and wastewater treatment plants/collection facilities and processes classifications can be found on the NFPA website ) Basically, NFPA 820 defines specific hazards and ways to prevent them in facilities where flammable gasses are produced during the collection and treatment of wastewater, most notably Hydrogen Sulfide (H2S) and Methane (CH4).

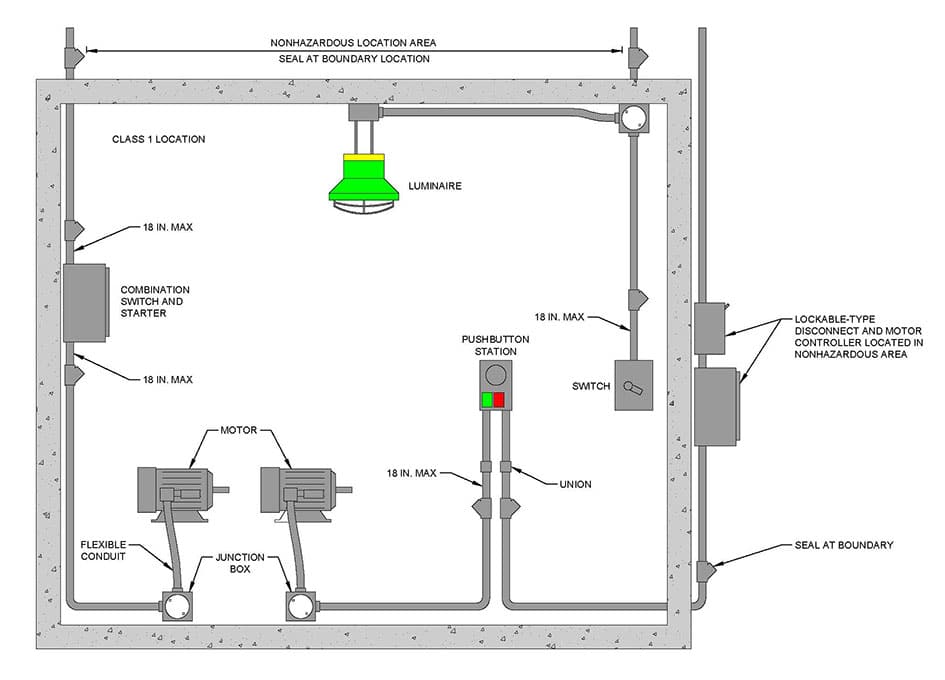

NFPA 820 provides guidance for controlling flammable gases with ventilation based on the distance from a source, or air exchanges, that will dissipate gasses produced during the conveyance or treatment processes to a non-hazardous level. The NFPA 820 code also allows physical separation of locations within an enclosed area. This separation creates a boundary between hazardous and non-hazardous locations in the wastewater treatment facility.

Helpful Tools

The National Fire Protection Association (NFPA) and the National Electric Code (NEC) provide several means and methods to use during design and upgrade projects for wastewater and collection facilities.

Access NFPA’s information here and NEC’s subscription information can be found here.