What You Need to Know About Fire Protection Systems in Mass Timber Buildings

Upfront Coordination and Planning are Essential for Successful Projects

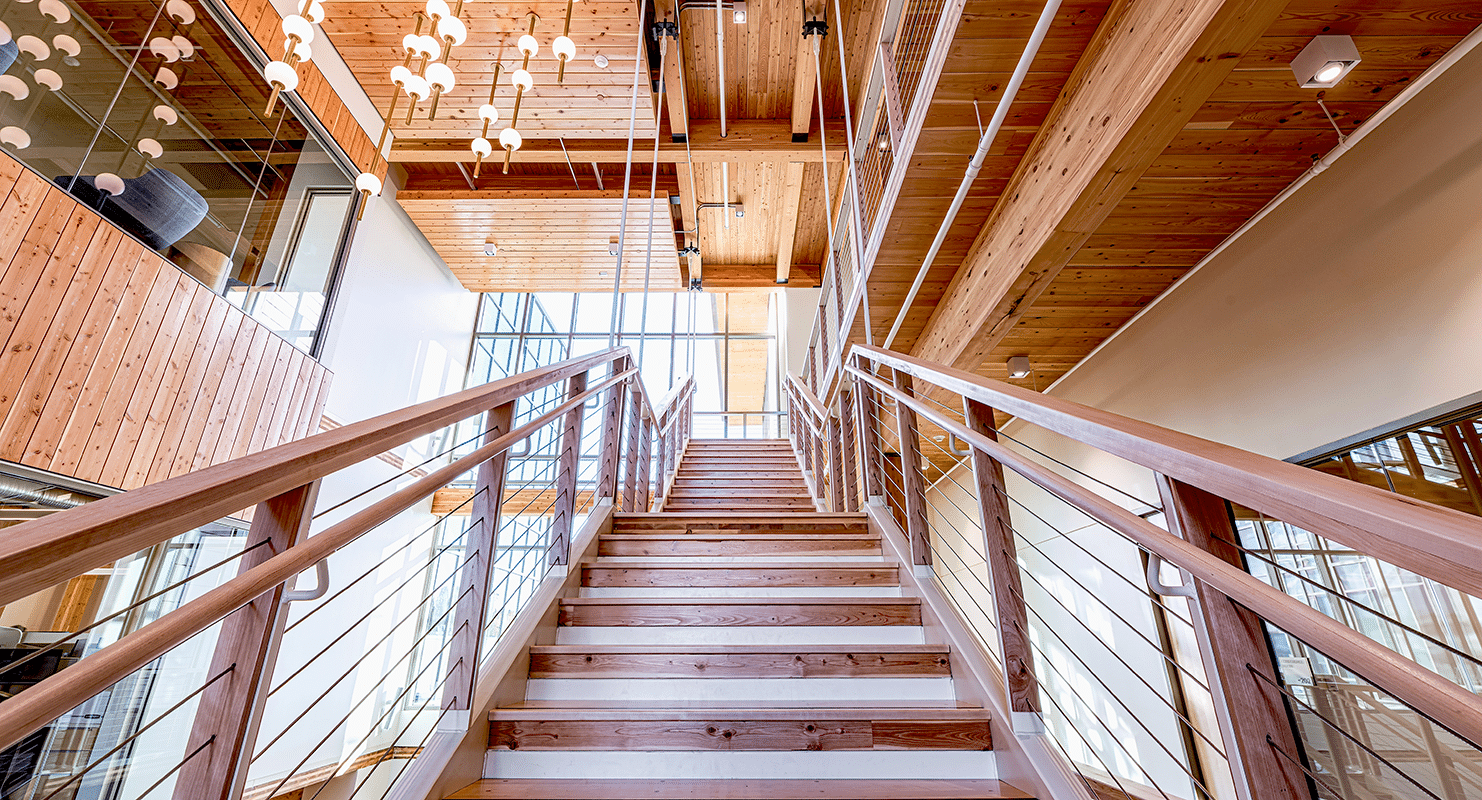

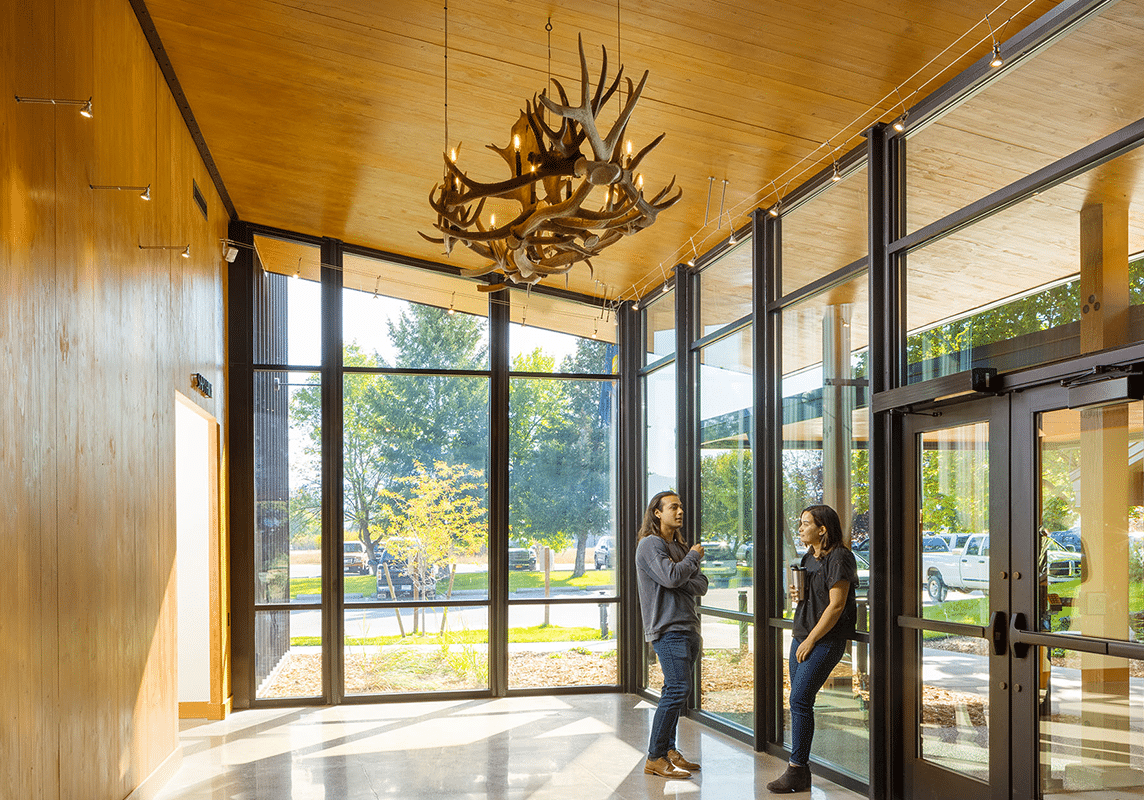

Designing and integrating fire protection systems into mass timber buildings presents unique challenges, even for the most experienced and creative design teams. While mass timber is often chosen for its natural warmth, visual appeal, and sustainability, balancing these aesthetic and environmental advantages with code-compliant fire protection requires strategic planning, early coordination, and a deep understanding of both materials and fire safety standards.

Below are key considerations and strategies to help ensure your next mass timber project achieves its design intent while meeting all fire protection requirements.

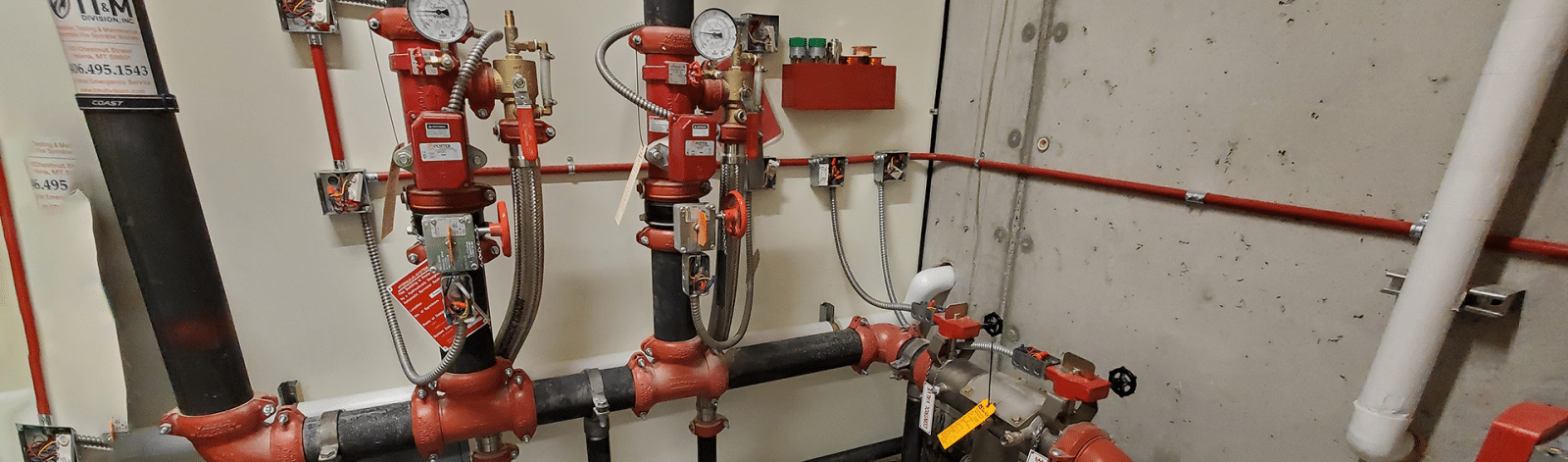

Start with Early Coordination: Fire Protection Is Not a Retrofit

The success of fire protection in mass timber starts with early and intentional planning. Without coordination from the start, concealing sprinkler piping, fire alarms, and mechanical systems within exposed timber elements becomes a nearly impossible task, often leading to aesthetic compromises. Incorporating fire protection engineers early in schematic design allows for:

- Thoughtful routing of piping and equipment.

- Strategic location of concealed chases in panels to limit wood fiber waste.

- Integration of recessed or painted sprinkler heads that blend with exposed timber ceilings.

In short, early engagement reduces cost, avoids design compromises, and preserves architectural intent.

Construction Type and How It Relates to Mass Timber

Determining the occupancy and construction type early in the design process can have a significant impact on the overall cost and efficiency of a project. While mass timber offers many advantages, selecting a mass timber structural system does not automatically mean that Type IV construction is the best choice. Type IV requires structural members to meet specific minimum size requirements to account for fire-related charring, which can result in larger, bulkier elements than the project might otherwise require.

If the occupancy classification and building limitations permit, using a different construction type or a hybrid structural system could allow for more efficient member sizing, improved space utilization, and greater design flexibility, all without compromising fire safety.

Understanding Fire Ratings vs. Flame Spread Index (FSI)

A common misconception is that the charring behavior of mass timber provides all necessary fire resistance. While it’s true that thick timber elements form a protective char layer that slows combustion, they are still classified as combustible materials under the International Building Code (IBC), NFPA standards, and ASTM requirements.

As such, codes prioritize not only structural fire performance but also surface flame spread. The Flame Spread Index (FSI) measures how quickly fire travels across a material’s surface and has a direct impact on design elements like:

- Exposed overhangs

- Concealed spaces

- Interior finishes

High-FSI wood species may require additional treatments, such as:

- Intumescent coatings

- Fire-retardant stains

- Additional sprinkler coverage

Designers must evaluate these factors early, particularly when seeking approvals for exposed timber or open architectural features.

Choose the Right Wood Species Early

While fire protection requirements are not the only reason to select a type of wood species, early coordination with the structural engineer and the mass timber supplier could reduce the required fire protection based on the wood species FSI. Different wood species exhibit different FSI ratings, which can influence whether supplemental treatments or barriers are necessary. For instance:

- Maple generally has a lower FSI than Red Pine.

- Engineered panels may incorporate treated layers or veneers with inherently lower FSI values.

Selecting an appropriate species early in the project streamlines fire protection strategies, avoids last-minute material changes, and helps maintain budget and design integrity. Keep in mind that different timber suppliers may utilize different wood species.

Not All Ceiling Mass Timber Products Are Created Equal

Mass timber systems vary significantly in terms of flexibility and compatibility with fire protection systems.

For example, DLT (Dowel-Laminated Timber) offers greater freedom for integrating utilities directly into panels and minimizes waste associated with cutting chases after manufacturing. DLT panels rely on all wood members oriented in a single direction. DLT panels are easier to fabricate in custom widths and have the ability to locate service chases. Prefabricated chase covers can also be provided to match adjacent panels, allowing fire sprinklers and other systems to be fully concealed.

By contrast, CLT (Cross-Laminated Timber) is more rigid due to its alternating layer orientation. Panels are typically manufactured in set widths based on supplier efficiencies (e.g., available board stock, press capacity, and shipping limits). Using non-standard panel sizes results in scrap material, increasing project costs. As a result, chases in CLT panels are usually routed after fabrication, which can limit the integration of fire protection systems.

Collaborating closely with structural, MEP, and fire protection consultants during early phases ensures systems are harmonized from day one. Additionally, the sooner the design team can finalize a structural system (DLT vs. CLT vs. others) and select a mass timber supplier, the sooner these efficiencies can be recognized in the design process.

Open Floor Plans and Architectural Features Require Custom Solutions

Mass timber designs often emphasize open-concept floor plans, exposed stairs, and atriums. While visually striking, these features frequently trigger additional code requirements:

- Water curtain sprinklers and noncombustible draft curtains may be required to separate open stairs from other floors for safe egress.

- Fire-rated glazing or smoke baffles might be necessary to limit vertical smoke and flame spread.

- Sprinkler placement must account for beam obstruction and maintain sufficient coverage without compromising visibility.

Conclusion

Mass timber presents incredible opportunities for beauty, sustainability, and innovation in modern architecture. But with these benefits come challenges, especially when it comes to fire protection. The key to success lies in:

- Early interdisciplinary coordination and mass timber supplier selection.

- Informed material selection.

- A deep understanding of code requirements and performance strategies.

With the right team and proactive planning, fire protection can be seamlessly integrated, allowing mass timber’s natural beauty to shine safely.

Want to learn more about integrating fire protection in your mass timber project? Contact us today—we’re here to help guide your team from concept to completion.