Bringing the Outside In – Put Your HVAC Equipment Indoors

By Jody Waverek, PE

Generally speaking, outdoor mechanical HVAC equipment, such as air-source heat pumps, are located outdoors for a reason: to extract or reject heat from the outdoor air.

With most construction projects, installing HVAC equipment outside of the building does not present a problem because the equipment either may not require a large amount of space or can be hidden on the backside of the building out of the view of the public or occupants.

However, in some cases, installing your mechanical equipment outside may not be feasible. Some reasons may include the following:

- Physical constraints where the project site has limited or no exterior real estate for conventional outdoor mechanical equipment.

- Architectural aesthetics where the owner and/or design team has determined that outdoor equipment must not be visible from any view.

- Extreme climate conditions exceed the low-end performance range for air-source heat pump operation.

- Radiated noise constraints are set forth by the owner, jurisdiction, or neighbors.

- Architectural elements such as sloping roofs, overhangs, or enclosures that prevent the recommended installation or operation of mechanical equipment.

If any of these situations apply to your project—and all other solutions, including rooftop designs, have been exhausted—you may want to consider placing the necessary air source heat pump units in a conditioned enclosure or “doghouse.”

How Do “Doghouses” Work?

To provide the best possible outcome, it’s helpful to understand how doghouses work.

In most instances, doghouses are only considered when outdoor air-source mechanical equipment, for reasons listed above, can’t be located outdoors. Such is the case when the mechanical system selected is an air-source heat pump in a region with a cold climate. Air-source heat pumps have limited ambient conditions where they can operate and still produce useful heat. Most modern heat pump equipment can operate effectively in conditions as low as -15°F. In extreme climates, winter temperatures can drop well below the equipment’s lower operating limits, rendering the unit non-functional.

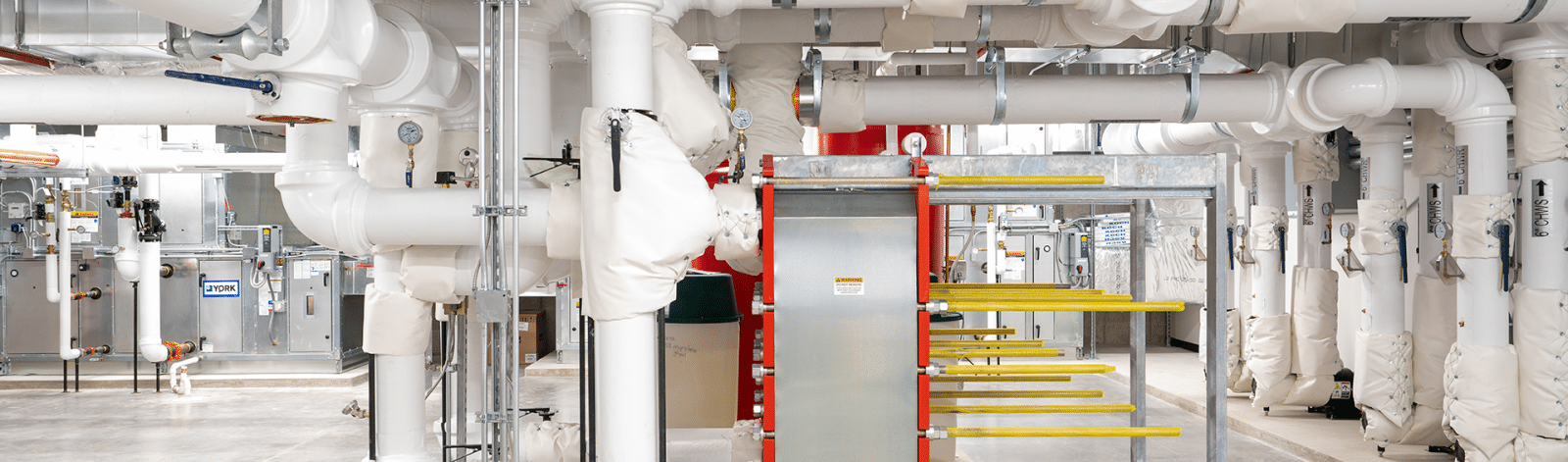

For example, the photo above shows a project where the equipment is located inside in an insulated enclosure, which provide automatic actuating louvers and a relief air system. When the equipment is in normal operation—which would be summer, fall, spring, or the shoulder seasons—where outdoor ambient conditions aren’t subzero temperatures, the equipment will operate just as it would if it were in an outdoor location. This means that the intake louvers are wide open and free to draw air from a low level. At that point, the air passes through the heat pumps, discharges from the top of the heat pump, and flows out of the vertical relief opening at the upper end of the doghouse. To simplify, the heat pump draws air to the bottom of the doghouse and rejects air through the top.

That’s how doghouses work for most of the year. The exception is when extreme temperatures in the wintertime prohibit the heat pump from operating properly. In this case, the automatic actuating damper on the intake and discharge louvers are set up on an outside air temperature sensor so that when the outdoor temperatures drop below a certain set point, the dampers close and there is no intake or relief. The heat pumps then operate by extracting heat from inside of this tightly enclosed space and then reject it to them where it is needed—the building’s occupied spaces.

In order for a doghouse to work in this scenario, we need to address one more element: the heat pumps, and the fact that they are extracting heat from the inside of a very small space. As the heat pumps extract heat from the air inside of the doghouse, they cause the temperature in the doghouse to drop. Now you are faced with making up that heat inside of the room somehow. This needs to be achieved via a secondary heat source.

One commonly used heat source is a natural-gas-fired unit heater. This heater must be appropriately sized to make up the exact amount of heat that has been removed from the room by the heat pump system. In this project example, we used a 400,000 BTU/hour input, natural gas-fired, unit heater to replace the heat extracted by the heat pumps.

Need to Know

Doghouses can be used in several building environments, from new construction to renovations. However, a few things must be considered before agreeing to design and construct one of these solutions.

While not common, keep the location of your doghouse in mind because noise can be a problem. The noise created by the heat pump will likely be fan noise, which may be objectionable. Compressors may also create noise that can be a nuisance to some occupants because they operate at octave bands that disturb many.

To avoid this, you’ll want to follow in our footsteps. In the pictured project, we put the heat pump in an isolated room with a well-insulated concrete foundation and detached it from the main living or office space. Avoid putting your doghouse on the second floor of an office building that is wood framed and adjacent to working environments.

Doghouses will also increase square footage. While you will need to pour more concrete, build more walls, insulate those walls, side them, and light them, it’s still a one-for-one exchange and equal to any other square footage of the building. Make sure you consult with your architecture and design teams to check for additional impacts created by the additional area.

Solutions for Many Projects

Like many project elements, each design solution has pros and cons. But for situations with confined space, architectural integrity requirements, and climate conditions, you may want to approach your design team about adding a mechanical doghouse solution to your next project. From commercial buildings to large industrial projects, a doghouse may be something you might want to consider.