Mystic Intake Gate Replacement

How to Create an Intake Gate Design for a Remote Location

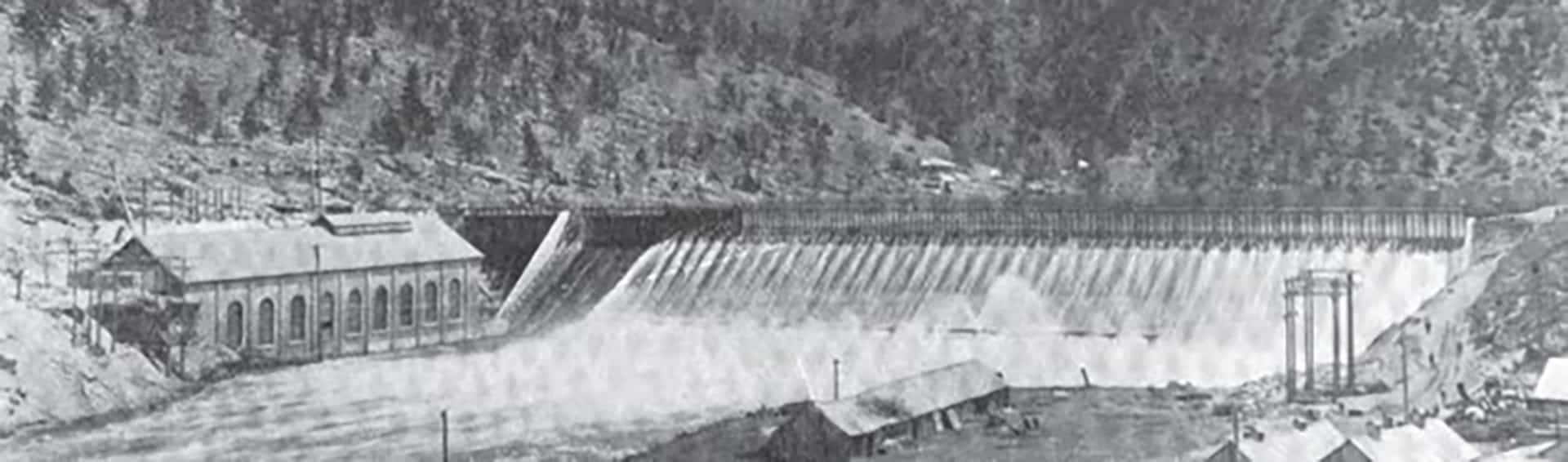

The Mystic Lake Hydroelectric Project and Rowe Dam were completed in 1927. This remote facility in Montana’s Beartooth Mountains has three dams, a concrete intake structure, flowline, penstock, and a two-unit Pelton-wheel turbine powerhouse. After several upgrades over the years and a short-term repair of the stem connection braces in 2022, Northwestern Energy committed to replacing the intake gate and related components. After an inspection in 2023 to gather information on the condition of the intake gate components, NorthWestern Energy decided to proceed with the design of the Mystic Intake Gate Replacement.

Services and Highlights

-

Civil engineering design

-

Structural engineering design

-

Operational analysis of the former intake gate

-

Site evaluation

-

FERC documentation

-

Construction administration

-

QCIP documentation

Project Background

The two main dams retaining Mystic Lake include a concrete arch and a concrete-faced earth-fill dike. The third dam is a re-regulating dam near the outlet of West Rosebud Lake, providing minimum flow releases into West Rosebud Creek.

Initially, the intake gate was constructed of wood timbers clamped together by steel threaded rods, with a riveted steel brace at the top to connect to the riveted steel H-section gate stem. In 1982, the wood gate timbers were replaced with built-up steel panels constructed of welded plate steel. The panels were stacked and clamped together similarly to the original wood timbers. The original stem bracket, stem, and stem guides were also maintained for continued use in 1982.

In 2008, the timber headgate wood seals were upgraded with the installation of flowline leak detection and dam failure instrumentation and controls.

Inspections in recent years showed high levels of rust and steel section loss in the gate, especially in the connection braces of the gate stem. Additionally, the wooden timbers above the gate opening and the existing keeper guides were significantly rotted. Visual observations also indicated that the gate stem and stem guides were rusted to the point of being ineffective.

Learn More About Our Projects at Mystic Lake

Mystic Intake Gate Replacement Project

Built By Hand and Helicopter

The most challenging aspect of this project was related to constructability, and Morrison-Maierle took this challenge into account from the beginning of the design.

The intake gate is located at 7,700 feet in elevation, surrounded by wilderness, not near any roads, and essentially 70 feet down inside a dark and partially submerged hole. The new gate and stem had to be designed to be flown to the intake by helicopter and assembled in place by NorthWestern’s crews by hand.

Morrison-Maierle considered the plant’s operations and the long winters, which resulted in a short construction schedule window. Because of this, all materials had to be on-site, and construction plans had to be thoroughly laid out before the work could begin.

Another consideration the team addressed was devising a design that utilized readily available materials and fabrication processes; this step was crucial to ensuring readiness before construction.

To meet these goals, Morrison-Maierle planned the construction schedule carefully to ensure that the design and construction documents were completed by September 2023. This design decision gave the team a seven-month period for FERC review and procurements before construction began in May 2024.

Following Guidelines and Regulations

Before developing a new structural design, Morrison-Maierle thoroughly inspected the existing gate and surrounding structure. They also analyzed the existing documentation for the gate system to ensure that the new gate design parameters would align with the operational capabilities. The new gate design had to comply with FERC guidelines and other relevant regulations for outlet works, dam operating equipment, and hydraulic steel structures.

The new gate was designed to accommodate all potential operating conditions, including withstanding the pressure from the Probable Maximum Flood. The designers developed a modular gate design using structural steel tubing, channels, and minimal hardware to connect the gate pieces. The stem was designed in multiple pieces with simple bolted splices, and new gate guide assemblies were designed to be anchored to the existing concrete. A coating system was used on the gate and applied to all surfaces to help render a long design life. In addition, the stem was galvanized for the same reason.

Morrison-Maierle coordinated with the fabricator, provided shop inspections, and closely coordinated with NorthWestern Energy in construction planning and inspection.

Learn More About Our Dams and Hydroelectric Plant Capabilities

Related Projects

Mystic Lake Flowline and Trolley Bridges

Morrison-Maierle provided engineering services for design and development of construction documents for the new steel trestle bridges along the Mystic Lake flowline hydroelectric project.

Holter Dam Spillway Concrete Repair

NorthWestern Energy hired Morrison-Maierle to help with the Holter Dam’s spillway concrete repair. Holter Dam is a 1,364-foot-long and 124-foot-high concrete embankment dam on the Missouri River.

Hauser Dam

The Hauser Dam project required surveying the space and replacing its old horizontally-designed turbine with a new vertically-designed version in the powerhouse that was built in the early 1900s.