Round Mountain Mill Flotation Expansion

Cost-Effective and Efficient Design

Founded in 1993, Kinross Gold Corporation is a gold mining company with a diverse portfolio of projects throughout the United States, Brazil, Chile, Ghana, and Mauritania. Headquartered in Toronto, Canada, Kinross employs approximately 9,000 people worldwide.

The Round Mountain Mine is an open pit mine in central Nevada, one of the most prolific mining districts in the world. Round Mountain uses conventional open-pit mining methods and processes ore by milling and heap leaching.

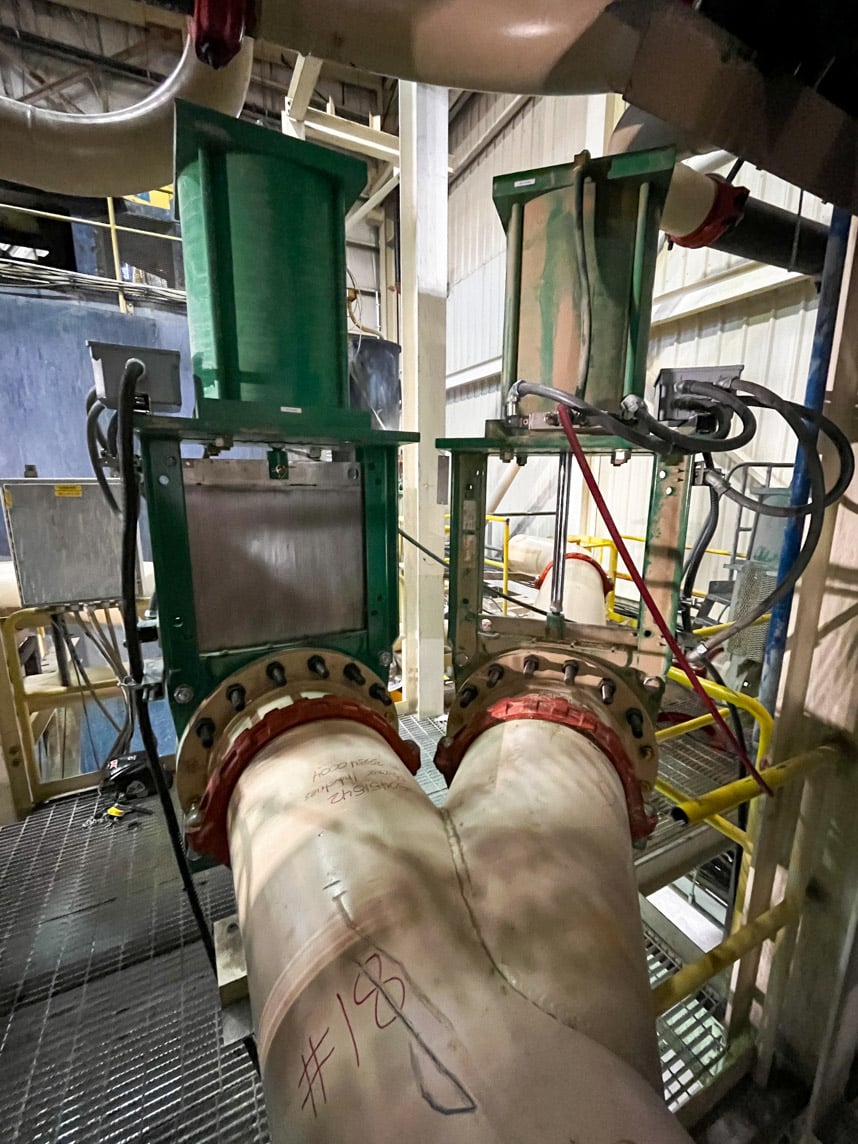

Round Mountain Gold Corporation hired Morrison-Maierle to design the expansion of an existing scavenger flotation circuit at the Round Mountain Mine. The project’s purpose was to add flotation capacity to increase gold recovery in the mill.

Morrison-Maierle provided detailed engineering, construction phase support, and commissioning support. A few highlights of the project included:

- To reduce costs and meet the owner’s needs in terms of overall capital expense, during the preliminary engineering of the project, we determined that we could eliminate the pre-engineered metal building that enveloped the expansion of the flotation circuit.

- We conducted a trade-off study to study the effects of four 160 cubic meter rougher cells versus three 200 cubic meter rougher cells. Going with three larger cells yielded the same processing capacity and recovery results with a $500k savings to the project budget.

Services and Highlights

-

Civil

-

Commissioning support

-

Construction phase support

-

Electrical engineering

-

HVAC

-

Mechanical

-

Structural

Supply Chain and Labor Shortage Issues

The rougher cells for flotation are generally only fabricated in two countries in the world, Mexico and Sweden. Because the rougher cells were purchased during ongoing supply chain issues that developed during the COVID-19 global pandemic, the owner chose to purchase cells that would be fabricated in Mexico. As a result, they were able to drive the rougher cells directly to the site instead of shipping them overseas on a barge, as would be required for the cells from Sweden.

The Flotation Expansion Project and the increased recovery through the mill provide the opportunity for the Round Mountain Mine site to reduce their cost to produce per ounce at the site. These improvements are essential for mining sites as it has been increasingly difficult to hire quality personnel.

Due to this labor shortage, sites are trying to do more with automation and processes to yield their budgeted ounces per quarter with the same number of or even fewer staff in operations and maintenance.

Reducing Costs and Infrastructure

Other mining operations will look to this circuit to check on the actual gold recovery improvements versus the targeted increase to confirm if their operations can also forego the cost of a building when they develop or expand their own flotation circuit. While the project has only experienced one winter season, the expanded flotation circuit did meet the targeted increase in gold recovery through the mill. Over time, the actual gold recovery should be trended to show long-term results.

Want to learn more about our mining project work? Contact Debbie Johnston.