Pump Station Problems: Tackling Deteriorating Impellers

By Kurtis DeShaw, PE

Water distribution managers are tasked with getting the most out of their pump station equipment. One of the things they focus on is preventing impeller deterioration or “chewing” at their pump stations. Chewing can lead to reduced pumping efficiency and increased maintenance, equipment, and operation costs.

While normal wear and tear are common, all pump stations should have an operations and maintenance plan to optimize pumping operations. Traditional operations and maintenance plans contain the following elements:

- Regular inspection for leaks and abnormal sounds.

- Bearing lubrication.

- Seal replacement.

- Packing replacement.

- Impeller replacement based on standard usage to optimize hydraulics as the impeller wears over time.

Even the best-laid maintenance plan can go awry, however, and other factors can lead to pump deterioration more quickly than standard wear and tear. Some common pump impeller deterioration problems observed in pump stations include:

Efforts to minimize accelerated impeller wear issues should take place in the design phase and during normal pump station operations.

Abrasive Wear Caused by Solids in the Water

This type of wear is typically reduced in drinking water pump stations due to higher levels of filtration, but occasionally, rocks or other debris will get trapped inside the pump and cause issues. This debris occurs much more frequently in raw water pump stations. Under rarer circumstances, gravel makes its way into the finished water system, most likely related to a construction project.

Chemical Reactions Between the Solution and the Impeller Material

This causes corrosion that ultimately deteriorates the impeller. Variables in the water can exacerbate these issues, such as the specific chemicals used for treatment, cavitation, and water temperature. How water operators chlorinate water may impact the corrosivity of the water on the pump impeller. For instance, sodium hypochlorite is more corrosive on water system equipment than chlorine gas, although it is much more user-friendly for operators.

Cavitation Occurs During Low-Pressure Situations

Low pressure can create vapor bubbles that collapse when subjected to higher pressures. The collapsed vapor bubble sends a powerful shock wave into the impeller that causes deterioration and premature wear. Occasionally there are unresolved hydraulic issues that can create this issue.

Some of these issues force the replacement of the impeller in as little as two years. In some cases, pump hydraulics will begin to diminish during higher flows and pump handoffs, which can result in an inspection. Impeller replacement is part of a standard operations and maintenance plan, but in this scenario, the replacement frequency is far beyond standard replacement times.

Identifying diminishing hydraulics can be challenging and can be due to various issues. Observation of supervisory control and data acquisition (SCADA) or live data flows and pressures is a great starting point. Analysis of the flow and pressure data can reveal the following:

Is it Time to Upgrade Your Pump Station? Learn More

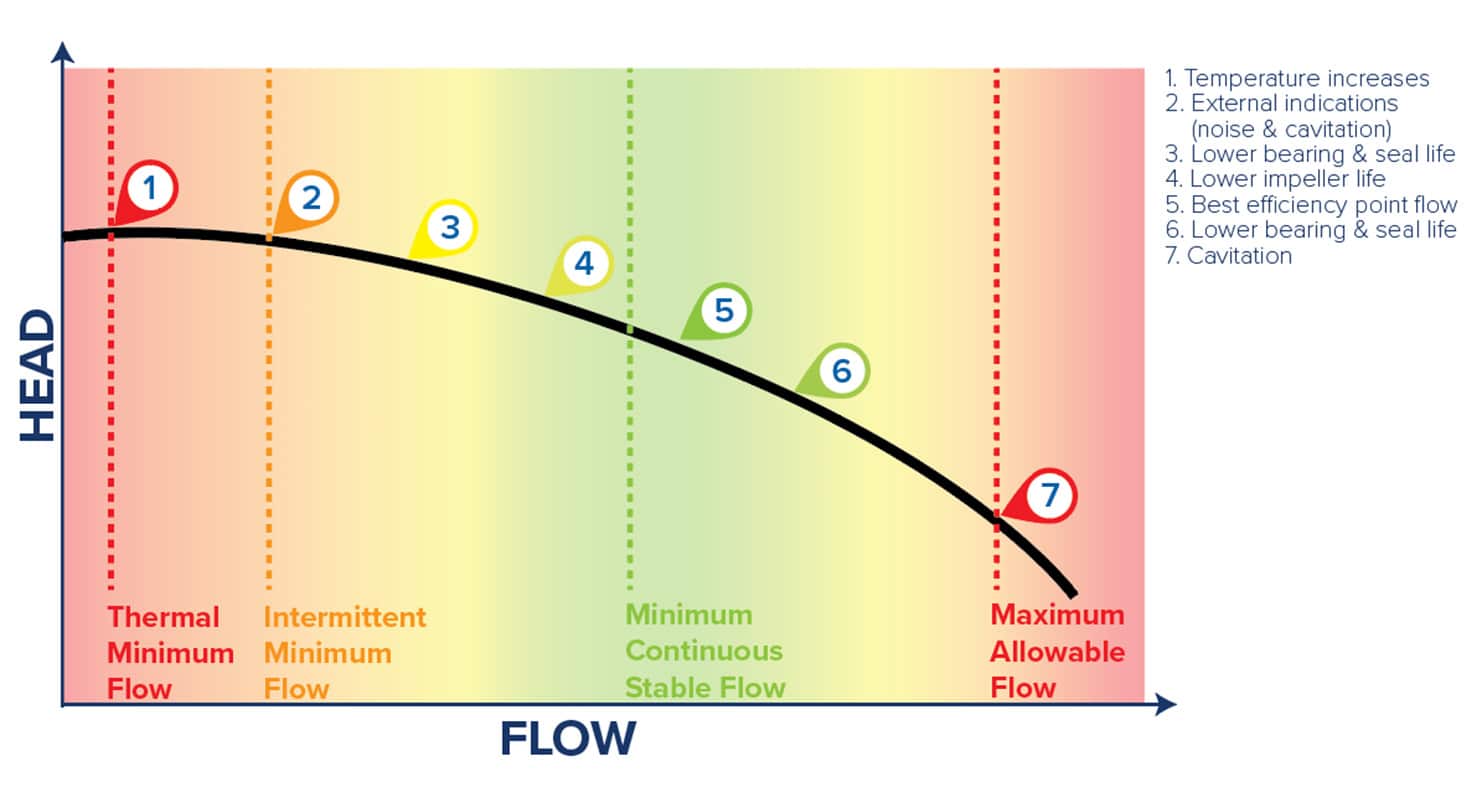

On the above graphic, the data to the far left shows that the pump is operating beyond the minimum continuous stable flow curve. Operations below this point can cause the following issues in increasing order of magnitude as the pump curve moves to the left of the minimum continuous stable flow curve:

- Pumping efficiency diminishes.

- Flows can become intermittent, starting to cause cases of cavitation and reducing impeller life.

- Flows become increasingly intermittent and non-stable, causing noisier operations, higher vibrations, reduction in bearing and seal life due to varying velocities and pressures around the casing volute, and more frequent occurrences of cavitation, which further deteriorates the impeller. As temperatures begin to rise, aggressive impeller deterioration and there is an increased probability of chemical reactions with the impeller (dependent upon water chemistry and pump impeller material).

On the graphic’s far right, the pump operates beyond the maximum allowable flow. Operations beyond this point cause the following:

- Dimished pumping efficiency.

- Frequent occurrences of cavitation that further deteriorates the impeller.

The handoff between pumps is not smooth. This can occur if there isn’t a delay to start the next pump in line or if the delay is too long or short. This issue will often be found in combination with one of the previous issues discussed regarding minimum continuous stable flow or maximum allowable flow. In addition, the pressure is not maintained in closed-loop systems. This will also often be combined with minimum and maximum flow issues.

Closed Loop Pump Station Problems

At closed-loop pump stations, pumping maintains pressure in a zone rather than pumping to reservoirs. This can create interesting phenomena. This is especially true with the smallest pump in the station.

In many cases, the impeller on the smallest pump frequently needs replacement. After a thorough analysis of several pump stations, we’ve found that:

- Minimum day demands were too low during nighttime to adequately circulate water. This causes the pumps to cavitate. During minimum day demands in some pressure zones, the average throughout the minimum day was more than 20 gallons per minute; however, at night, the demand was practically zero, with only the occasional toilet flush or late shower. As previously discussed, the pump operates at the far left of the pump curve during the night beyond the minimum stable continuous flow curve. This causes the cascade effect of reducing pumping efficiency, increased occurrences of cavitation, and, eventually, a temperature rise. The higher temperatures also increase the likelihood of chemical reactions. These issues are exacerbated when closed-loop pump stations are “churning” water due to low demand.

- Pump curves did not fit the system’s hydraulics. The operation of the pump curve is below the minimum stable continuous flow curve or beyond the maximum allowable flow. This causes the pumps to operate outside their range of best efficiency and speeds up the wear and tear on the impellers.

- The hand-off point between the pumps was too long and caused the pumps to operate beyond the maximum allowable flow for an extended period before starting the next pump in line. When handing off to a smaller pump, it can cause the pump to operate for an extended period below the minimum stable continuous flow curve.

The hand-off point between the pumps was too short and caused frequent start/stops and unstable flow conditions.

What You and Your Operations Staff Can Do

Efforts to minimize accelerated impeller wear issues should take place in the design phase and during normal pump station operations. Things you can do during the design phase are:

- Select the proper pumps with appropriate pump curves to meet system hydraulics.

- Evaluate the hydraulic design conditions when selecting the impeller material.

- Evaluate night flows during minimum day demands to determine if flows are too low for the smallest pump (don’t design the low end of the smallest pump on the average minimum day demands).

- Consider adding a bypass that operates only during small pump operation so the pump operates near its best efficiency point.

- Evaluate water chemistry to verify that a chemical reaction isn’t happening dependent on other issues (e.g., cavitation/boiling of water).

Things your operations staff can do to maximize impeller life are:

- Upgrading impellers to nickel-aluminum-bronze version. These are more resistant to cavitation than standard cast iron impellers.

- Taking water samples to verify that a chemical reaction isn’t happening independently of other issues (e.g., cavitation/water boiling). Replace the impeller with a corrosion-resistant material such as stainless steel.

- Replacing the smallest pump if there is a pump with a better hydraulic fit.

- Adding a bypass from the suction to the discharge header would allow enough flow to operate the small pump efficiently.

- Hiring an engineer to evaluate your pump station.

Taking the proper steps to reduce and eliminate premature deterioration of pump impellers will save money. This will also deter costly replacements of impellers by tackling the issue during any stage of design or operations.