Hebgen Dam Outlet Rehabilitation

NorthWestern Energy hired Morrison-Maierle to conduct a feasibility study and rehabilitation design for the Hebgen Dam Outlet Pipe. Located at the headwaters of the Missouri-Madison hydroelectric project, Hebgen Dam plays a key role in water storage and management for eight downstream power plants.

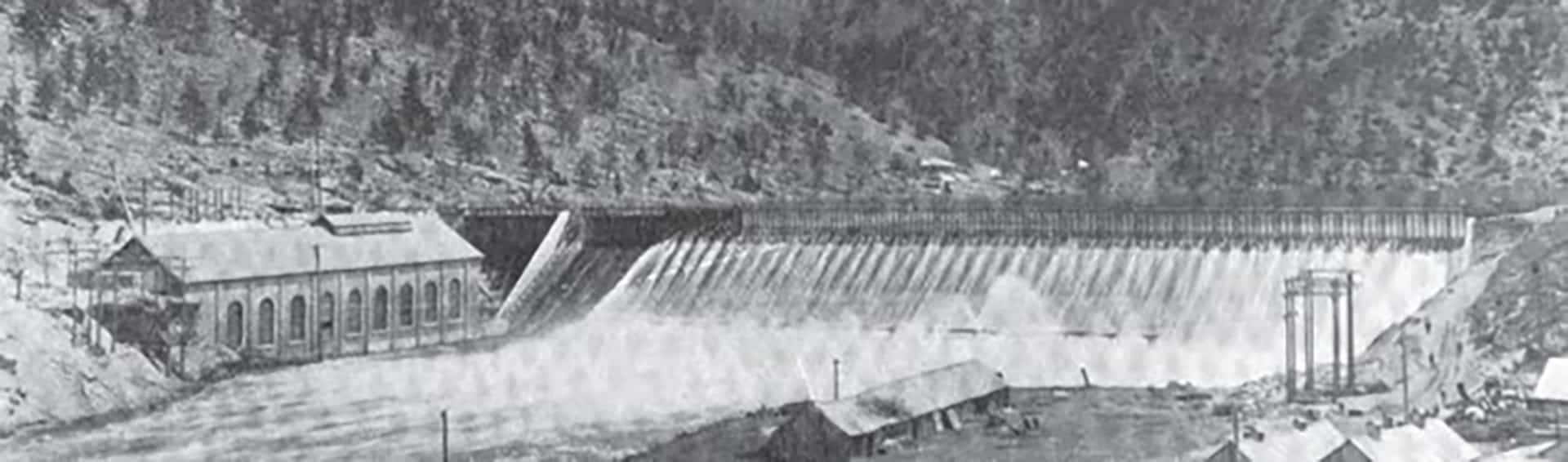

Hebgen Dam is a storage reservoir on the upstream end of NorthWestern Energy’s Missouri-Madison FERC project, consisting of eight run-of-river hydroelectric plants. This 80-foot-tall, 700-foot-long earth embankment dam holds back more than 300,000 acre-feet of water. It relies on a gated intake structure that directs water into a 12-foot-wide outlet pipe running beneath the dam—its primary low-level release point to regulate flow. An auxiliary spillway near the right abutment provides additional control when needed.

A Look Back: How This Project Came to Be

Hebgen Dam sits just a few hundred feet from a fault line, meaning it faces significant seismic activity. In 2010, NorthWestern Energy launched a series of upgrades to make the dam more resilient to earthquakes. Over the years, they strengthened key structures, completing intake structure repairs in 2016 and replacing the spillway in 2017.

During these upgrades, the team identified another essential need—the modernization of the outlet pipe, a critical infrastructure that regulates water flow.

Upgrading a Century-Old Outlet Pipe

The original outlet pipe was constructed with a wood stave lining and steel hoops. Initially, the lining was encased in unreinforced concrete, and the core wall and dam embankment were built over it. After a century of use—and surviving the 1959 earthquake—it became apparent that the pipe would require rehabilitation.

Morrison-Maierle’s involvement in this project began with a detailed feasibility study to evaluate options that helped NorthWestern Energy decide on a course of action. Some factors included:

- Cost

- Constructability

- Longevity

- Hydraulics

- Seismic resistance

- Compatibility with potential future hydropower.

After weighing different rehabilitation methods—including shotcrete lining, carbon fiber reinforcement, and steel slip lining—we determined that shotcrete lining was the best choice for both design and construction.

Why Shotcrete Lining?

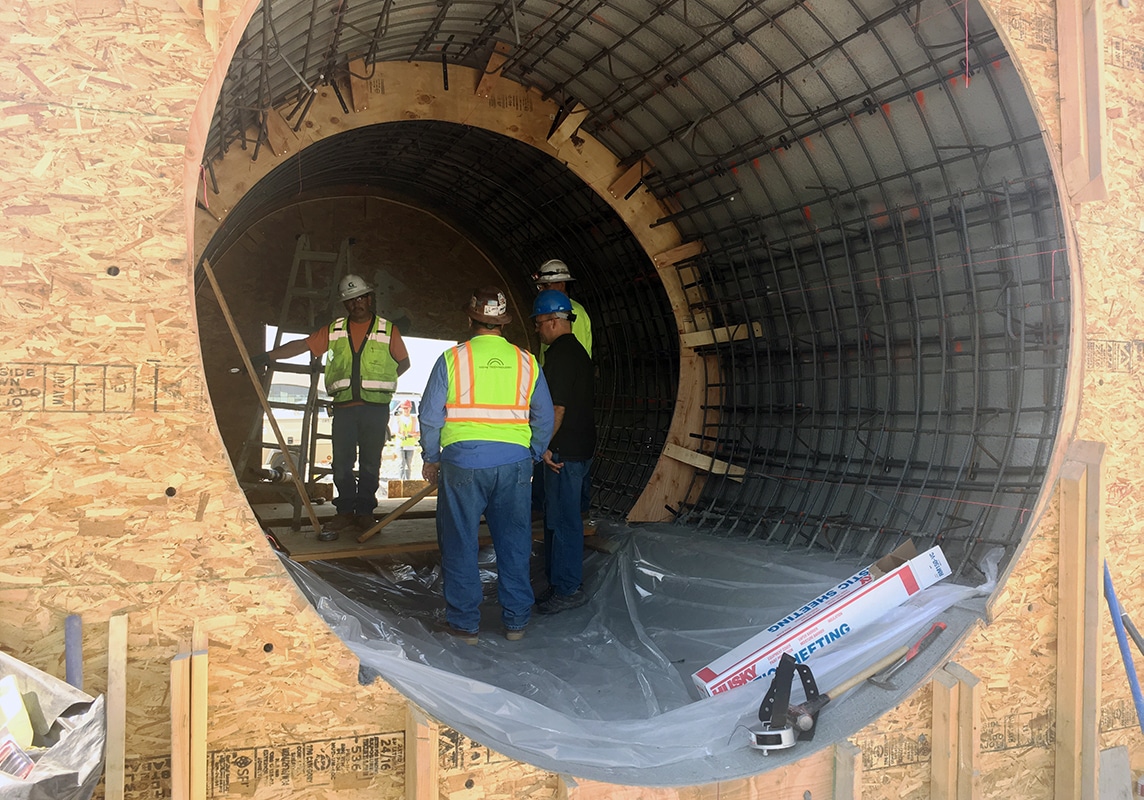

Cost and durability are the main advantages of reinforced shotcrete lining. Constructability was favorable but required unique specifications to complete the work correctly, including adding a skilled and knowledgeable contractor as an integral team member.

Shotcrete is a widely used material, but overhead application and long pumping distances are not common. We developed specifications tailored to the unique project and worked with the owner and contractor to integrate unique risk-reduction steps such as a mock-up test.

We contributed engineering support for the FERC project authorization, as performing any work within an embankment dam while retaining a full reservoir has serious risks that must be well understood and mitigated.

Learn more about our bridge services.

Finally, our team also provided construction administration with material testing and on-site observations. This included arranging a remote, on-site testing laboratory trailer, allowing the team to forgo transporting materials two hours away to another testing facility.

Despite the work area’s unique design, remote location, and challenging configuration, the project team’s strong collaboration and careful planning made the construction successful.

Learn more about how Shotcrete Can Be Used to Repair and Rehabilitate ConcreteRelated Projects

Holter Dam Spillway Concrete Repair

NorthWestern Energy hired Morrison-Maierle to help with the Holter Dam’s spillway concrete repair. Holter Dam is a 1,364-foot-long and 124-foot-high concrete embankment dam on the Missouri River.

Morony Dam Spillway Modifications

Morrison-Maierle provided procurement specifications for the new gates, hoists, heated guide system, construction sequencing for the spillway and pier modifications, and hoist house enclosure design.

Hauser Dam

The Hauser Dam project required surveying the space and replacing its old horizontally-designed turbine with a new vertically-designed version in the powerhouse that was built in the early 1900s.