Mill Flotation Improvements Value Engineering Study

Optimized Process Also Saves Money

Founded in 1993, Kinross Gold Corporation is a gold mining company with a diverse portfolio of projects throughout the United States, Brazil, Chile, Ghana, Mauritania, and Russia. Headquartered in Toronto, Canada, Kinross employs approximately 9,000 people worldwide.

The Round Mountain Mine is an open pit mine located in central Nevada, one of the most prolific mining districts in the world. The location of the proposed Mill Flotation Expansion Project is adjacent to the existing Round Mountain Mill facility approximately 55 miles north of Tonopah, in Hye County, Nevada. The mine and mill are operated by Round Mountain Gold Corporation (RMGC).

Service & Highlights

-

Value Engineering Study

-

Changes implemented during the study saved the mine $5,733,530 compared to the initial design.

-

Structural engineering

-

Process engineering

-

Civil engineering

-

Electrical engineering

-

Mechanical HVAC engineering

-

3D modeling

RMGC wanted to study the potential for gold recovery in their milling facility through the expansion of their flotation circuit. They had initially worked with Samuel Engineering who developed a feasibility study proposing the Mill Flotation Expansion Project. Morrison-Maierle’s Value Engineering Study Scope of Work evaluates the proposed project to ensure

that the project scope has been optimized.

Starting with key project elements, as outlined by RMGC, Morrison-Maierle adopted a “nothing is sacred” approach that supported challenging assumptions and questioning all previous project design tactics. By challenging original design assumptions, while further developing design approaches, the team was able to leverage their recent project site design and construction experience to yield safe, constructible, maintenance-friendly, and economical design solutions.

As a result, the Value Engineering Study focused on the following key project elements:

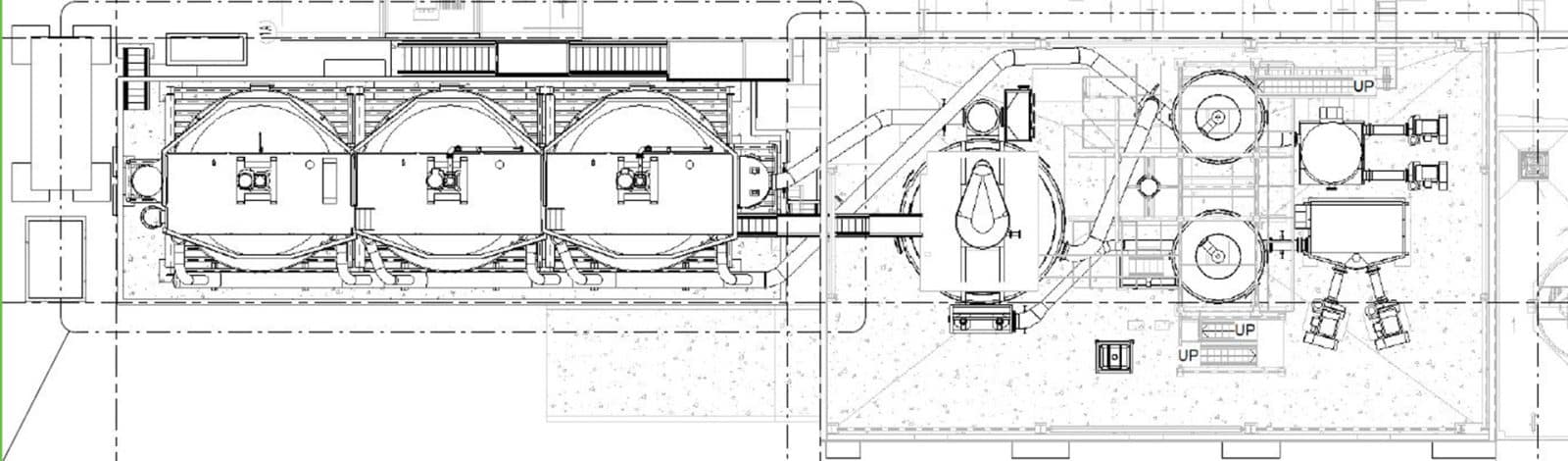

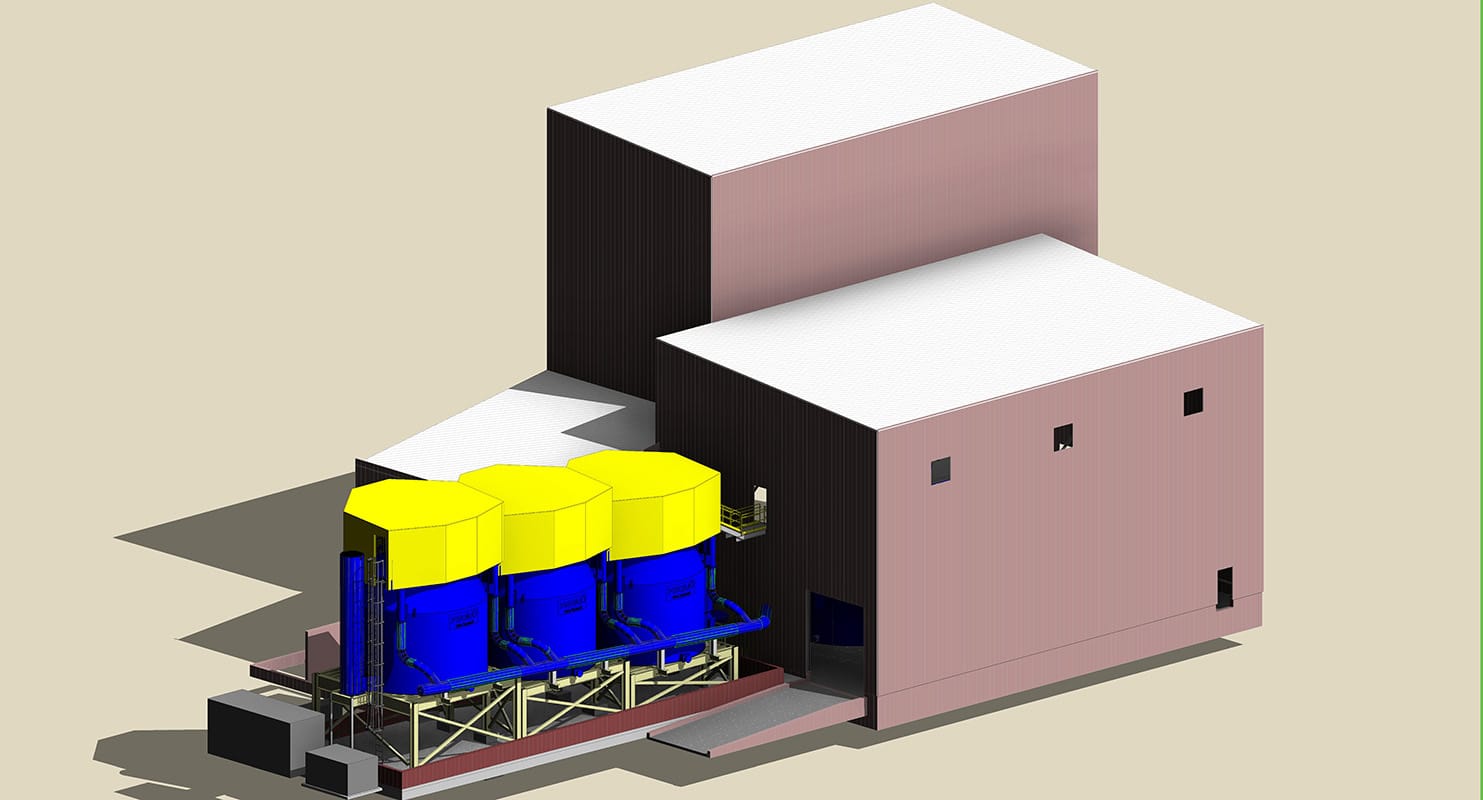

- Minimize the proposed pre-engineered metal building (PEMB) footprint to house the flotation expansion equipment and remove unnecessary access platforms.

- Evaluate the bridge crane proposed in the Feasibility Study compared to roof hatches to accommodate access to the external crane.

- Use the revised RMGC single-line diagram to optimize the FS electrical requirements and utilize low-voltage gear where possible.

- Evaluate alternative flotation process equipment arrangements to use three rougher cells instead of the four cells proposed in the Feasibility Study.

- Remove the backup blower from the design, but leave floor space, piping, and electrical designs intact to allow for a future expansion.

- Produce a concrete and structural design to reduce contingency requirements.

- Produce a capital cost estimate for the optimized project.

Morrison-Maierle drafted and transmitted it to RMGC for review. Changes implemented during the study saved Round Mountain $5,733,530 compared to the initial design.

Related Projects

Round Mountain Mine Phase W

Kinross selected Morrison-Maierle to perform detailed engineering for various infrastructure and processing needs for their significant mine pit relocation and expansion.

City of Missoula Cogeneration System Upgrades

The City of Missoula Cogeneration System uses the biogas produced at its wastewater treatment plant to create its own heat and electricity to power the plant.

Marigold Mine Tank Structural Assessments

Morrison-Maierle to conduct a non-destructive structural assessment of three cyanide liquid holding tanks at the Marigold mine.