Morony Dam Spillway Modifications

A New Way to Prevent Ice Buildup

Due to ice buildup, the radial gates on the Morony Dam spillway were not operating correctly in the winter. NorthWestern Energy asked Morrison-Maierle to conduct a feasibility study to address this issue and found the best remedy: replacing the radial gates with new vertical lift gates with an internal heating system.

To ensure this solution performed correctly, Morrison-Maierle analyzed the existing stability of the dam to ensure the modifications would be acceptable. A preliminary hydraulic analysis of the proposed spillway configuration and subsequent spillway rating curve was developed to ensure flow compliance.

Morrison-Maierle provided procurement specifications for the new gates, hoists, heated guide system, and construction sequencing for the spillway and pier modifications, as well as the design of the new elevated hoist house enclosure.

Finally, Morrison-Maierle provided on-site inspections and construction observation to ensure compliance with the design drawings.

Services and Highlights

-

Civil engineering design

-

Structural engineering design

-

Specifications for manufacturing

-

Inspections

-

Commissioning

-

FERC design report review

-

Preliminary hydraulic analysis

A Solution for a Cold-Weather Climate

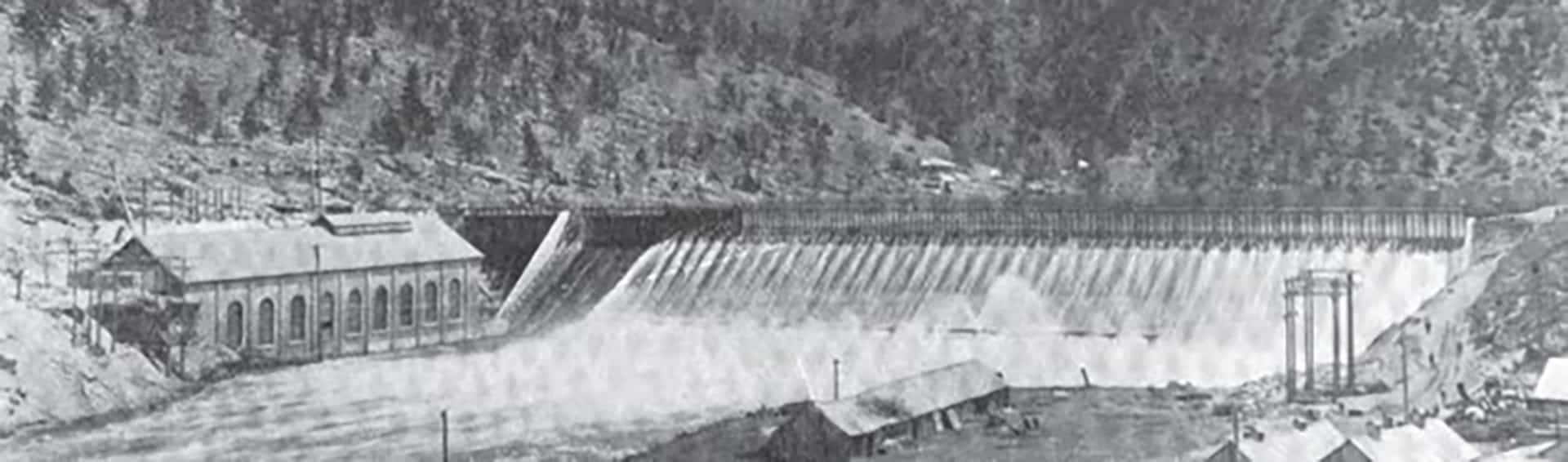

Morony Dam is a hydroelectric gravity dam on the Missouri River in Cascade County, Montana. It is owned and operated by NorthWestern Energy and generates 48 megawatts of power. The dam is 883 feet long and 94 feet high and has a 390-foot-wide spillway. The spillway has nine tainter (radial) gates with an overall gated width of 376 feet and one sluice (trash) gate with a width of 14 feet to regulate water flow down the spillway. The headrace for the powerhouse and the powerhouse itself are on the dam’s north side.

The existing tainter gates were susceptible to ice buildup around the seals, so NorthWestern Energy determined that modifications were necessary to use the gates during the winter. Together with its client, Morrison-Maierle determined that the most effective solution was to replace the tainter gates with new heated vertical roller gates designed to prevent ice buildup.

A Two-Phased Approach

Morrison-Maierle divided the project into two parts—Phase I and Phase II. In Phase I, we developed a conceptual design for modifying the Morony spillway by installing new vertical slide gates. We created a procurement package consisting of layout drawings and specifications for the new vertical roller gates, guides, heating assemblies, hoists, hoist superstructures, and all ancillary items. NorthWestern Energy used the procurement package to secure bids before hiring a contractor.

In Phase II, Morrison-Maierle finalized an evaluation of the existing dam stability for the new gate design developed by McMillen. The evaluation of the existing dam stability was included in the FERC design report which was reviewed by Morrison-Maierle. Morrison-Maierle worked as the Owner’s Representative to review gate, hoist, and support structures design. We provided inspection of the construction operations to document compliance with the design specifications and aided in submittal and RFI review.

Learn More About Our Dams and Hydropower WorkRelated Projects

Hauser Dam

The Hauser Dam project required surveying the space and replacing its old horizontally-designed turbine with a new vertically-designed version in the powerhouse that was built in the early 1900s.

Madison Hydroelectric Plant Powerhouse

Morrison-Maierle was the design engineer for the civil improvements to replace the 4 original 100-year old turbine and generator units at the Madison Hydroelectric Plant Powerhouse.

Thompson Falls Radial Gates

NorthWestern Energy hired Morrison-Maierle to develop a plan to increase gated spillway flow capacity on the main dam at the Thompson Falls Hydroelectric Project.