Reserve Street Lift Station

Saving Energy and Costs

The original Reserve Street Lift Station was constructed around 1965. It was a wet-well and dry-pit style. In 1983, it was relocated with the widening of Reserve Street, one of the busiest streets in Montana. Around 2007, the city started a plan to rehabilitate the Reserve Street Lift Station, only to halt the following year when the recession hit. Finally, in 2018, funds were again available to rehab the Reserve Street Lift Station. The city hired Morrison-Maierle to assist with these improvements.

Before Morrison-Maierle’s team got started, the city asked them to review the flows and verify the station from the 2008 design. Morrison-Maierle found that the lift station was seeing a higher growth in flows. Consequently, the city decided to reconsider the initial design of the Reserve Street project.

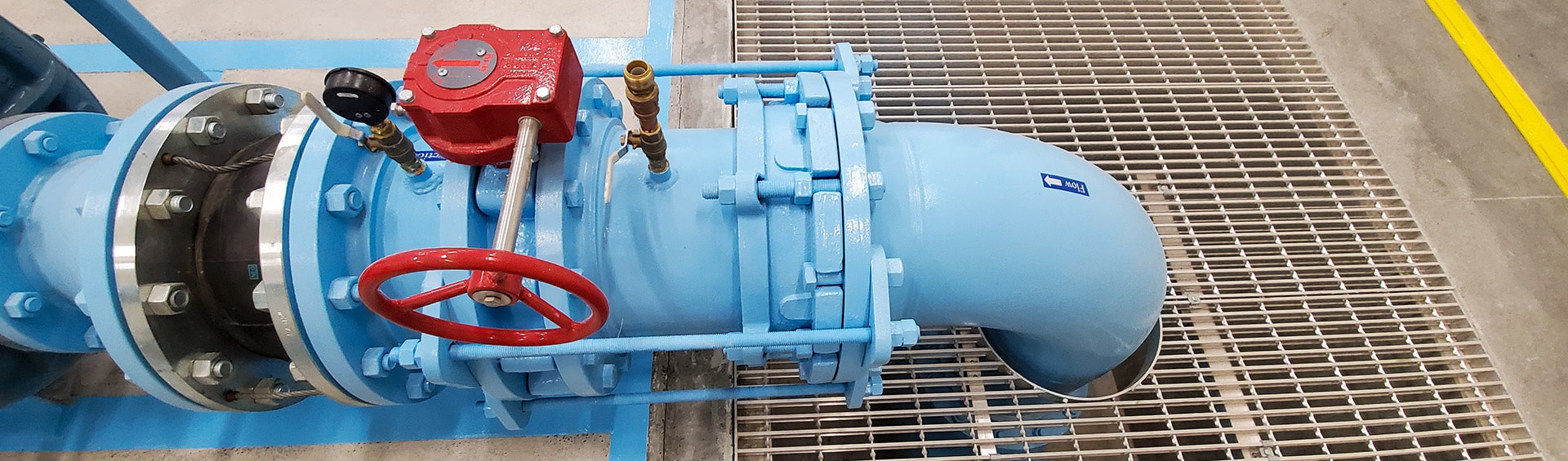

After careful study and planning, Morrison-Maierle proposed moving from a two-pump to a four-pump system. This configuration results in smaller pumps with less horsepower, but greater responsiveness due to changing flows throughout the day. The pumps also used Variable Frequency Drives (VFD), which allow the lift station to come on and stay on rather than shutting on and off multiple times during the day.

Services and Highlights

-

Civil engineering

-

Survey

-

Utility coordination

-

Montana Department of Transportation coordination

-

Preliminary design

-

Final design

-

Bidding services

-

Construction administration

-

Project closeout

Optimized for Efficiency and Cost Savings

Morrison-Maierle completed a bore on-site to locate groundwater. It showed that the contractors could encounter groundwater at about 7 to 10 feet from the bottom. This would be an issue when applying the necessary coating to the rehabbed wet well.

Morrison-Maierle evaluated how they could reduce the depth of the wet well to avoid the groundwater by working at a time when groundwater was at its lowest. Morrison-Maierle decided to offset the new wet well away from the existing one so the new lift station could be constructed, tested, and put into operation while minimizing construction within the old wet well. The new one is approximately three feet shallower than the former wet well.

In addition to the depth question, Morrison-Maierle developed a strategy to construct the project during the winter to address potential groundwater problems and reduce the amount of bypass pumping of sewer flows. The project was completed in April 2020, just four months after construction started.

The decision to use precast concrete structures was also factored into the proposed construction schedule and the winter weather. Incorporating precast concrete systems into the design allowed the contractor to assemble the wet well and valve vault during some of the coldest days in February and March. Precast also minimized the need for additional cold-weather tenting and heating for concrete pours which helped reduce project costs. Finally, given the depth of the wet well, precast allows for timelier backfill operations and eliminates the need to wait for concrete cylinder breaks.

Bypass Pumping and Future Development

Bypass pumping can be very costly when rehabbing an existing lift station. Given the flow (2,000 gpm) and potential duration (6 to 10 weeks) at Reserve Street, Morrison-Maierle determined the city would incur a $50-70K expense on bypass pumping alone. By offsetting the new wet well, the design team reduced the amount of bypass pumping required during construction and saved the city money.

Finally, Morrison-Maierle’s focus turned to the pumps themselves. Knowing that there was an increasing demand in the area, they determined that a three-pump solution with a slot for a fourth would be the most favorable solution. Allowing pumps to run longer would provide greater efficiency in pump operation and create less wear and tear. The team also found that there were significant electrical savings related to lower horsepower pumps and demand charges.

Combining the multi-pump system with the use of a VFD allows for maximum efficiency. Rather than using a single large pump that starts and stops (even with the use of a VFD), the smaller pump system also provided a better flow range to adjust to the diurnal flow pattern.

As a result, the City of Missoula now has ample levels of service for existing and anticipated use and realized an instant $500 month savings in energy expenses. These savings allow the city to pay off the additional pumps in 20 years as a result of reduced demand.

Related Projects

Whitefish Water Treatment Plant

The Whitefish WTP Expansion project shows how necessary upgrades, reclassifying a facility, and fast-tracking equipment procurement can be accomplished on a rapid timetable.