Columbus Warehouse Expansion

Upgrades for future mine infrastructure expansions

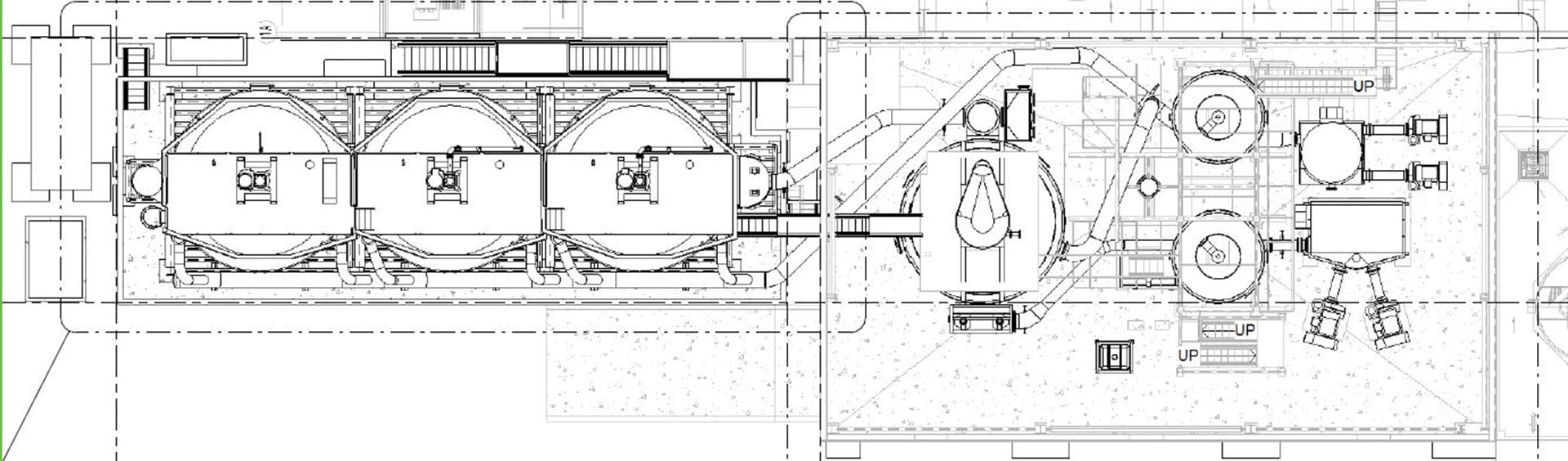

Sibanye Stillwater selected Morrison-Maierle to design upgrades for its Columbus Warehouse Expansion project. The mine needed to consolidate office space and relocate some personnel to its warehouse. The warehouse administrative space was modified to accommodate these changes to create new workspaces. In addition to providing conceptual designs for a future distribution center addition, we also analyzed options for warehouse logistics to increase operational efficiencies.

After examining several options, we provided best practices for general warehouse storage, pallet racking, cross-docking, and loading dock safety. We also made recommendations to improve warehouse operations, such as organization, inventory management, space utilization, and safety.

Services and Highlights

-

Structural, mechanical HVAC, plumbing, and electrical engineering services.

-

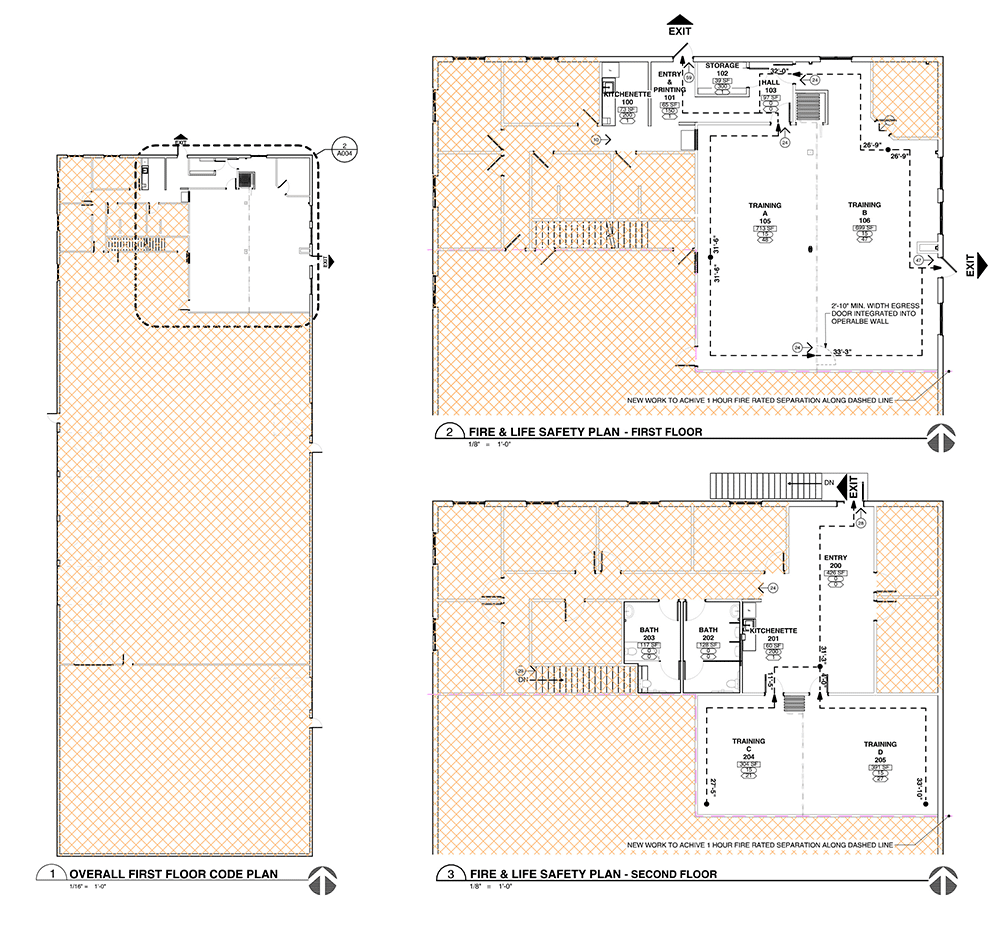

Redesign of the first-floor conference room into a training room with a floor-to-ceiling room divider and a storage room.

-

Addition of a walk-up window for permitting to decrease vendor foot traffic inside the warehouse.

-

Building out the second-floor space to add a new conference room with a floor-to-ceiling room divider and relocating the kitchenette to the open-seating area on the second floor.

-

Addition of restrooms next to the mechanical room on the second floor.

-

Upgrades to the site access and security system.

-

New interior parts pick-up area with restricted access.

-

Design of a covered area on the east side of the current warehouse for cold storage.

-

Site lighting upgrades.

-

Loading dock upgrades, including covered parking, new concrete ramps, existing concrete surface repairs, and upgrades of existing railing.

-

Definition of fire suppression systems to provide designs for current and future expansions.

-

Conceptual designs for a future distribution center.

-

Execution of AutoTurn models to review truck turning movements in and around the site.

-

Analysis of options for warehouse logistics to increase operational efficiencies, an evaluation of best practices for general warehouse storage, pallet racking, cross-docking, and loading-dock safety.

Project Background

Sibanye-Stillwater is a multinational mining and metals processing group with a diverse portfolio of operations, projects, and investments across five continents. It owns and operates the Columbus metallurgical complex, a smelting facility and base metal refinery situated near the Stillwater Mine. It is one of the world’s largest producers of US Platinum Group Metals (PGM) recycled from automotive catalytic converters.

The Columbus metallurgical complex comprises a smelter with a concentrate drying plant, two electric furnaces, two top-blown rotary convertors, a matte granulator, and gas handling and solution regeneration systems. The smelter’s maximum design capacity is 20,000 lbs./hour (operates at 90% utilization), which is limited until upgrades to the concentrate drying plant and convertor/granulation circuit are completed. These improvements will ensure the capacity as the smelter aligns with the increases in production from the Stillwater East (formerly the Blitz Expansion Project) and East Boulder mines.

In addition to the smelter, the base metals refinery has a capacity of 1,300 lbs./hour of matte but is limited by its overall copper electrowinning (EW) capacity. The copper EW circuit operates 24/7, even though the rest of the plant only operates approximately half a week. As a result, the copper circuit had to be expanded to accommodate the increased quantities of copper that the Stillwater East and East Boulder operations can now deliver.

Learn More About Our Industrial Engineering Services

A Two-Phased Approach

In Phase 1 of the project, consolidating office space and relocating some personnel to the warehouse, we performed structural, mechanical, HVAC, plumbing, and electrical engineering services to produce construction drawings and specifications for the modifications. Our scope of work included redesigning additions and features to allow for more space and to accommodate growth and future development. See “Services and Highlights” above for more details.

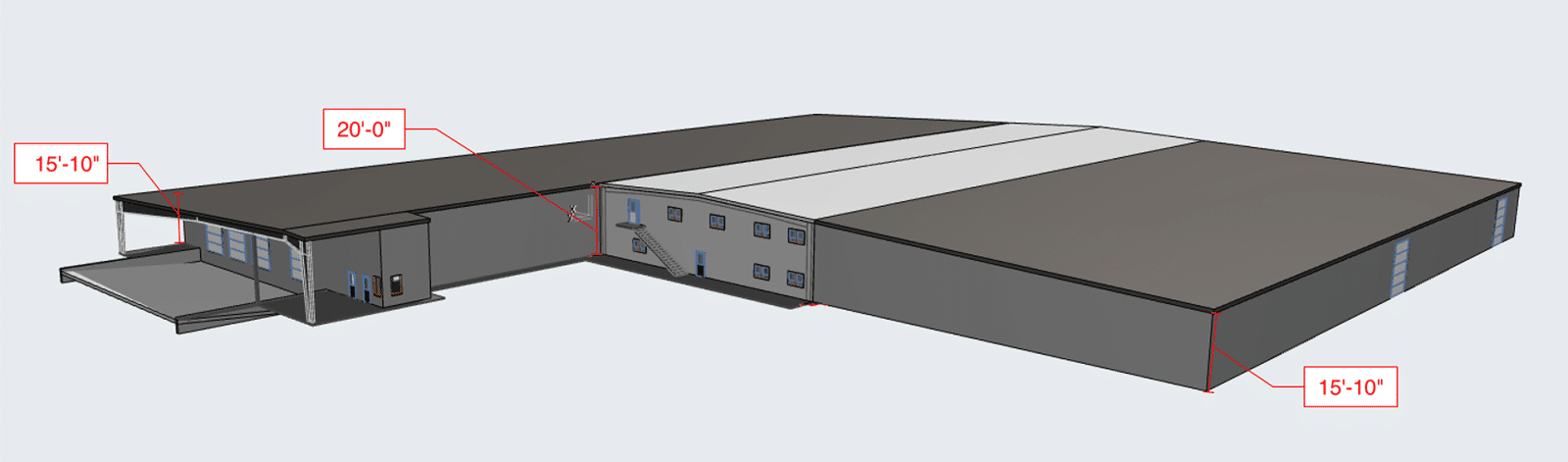

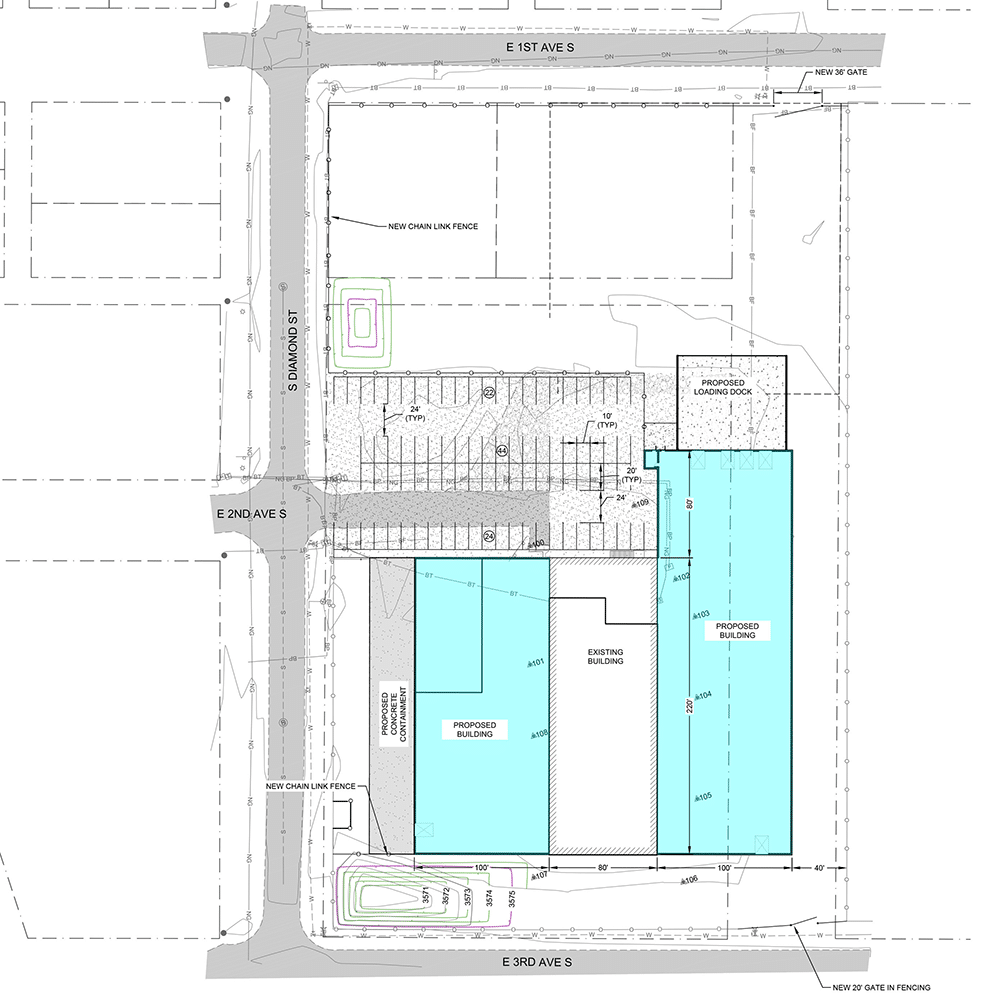

Phase 2 included engineering services and construction plans to provide a possible future distribution center for the Stillwater Mine. This effort included an overall property site plan depicting layouts with scenarios with and without property acquisition and traffic-flow patterns. AutoTurn models reviewed truck turning movements in and around the site. Our structural and electrical teams developed preliminary building frames to explore how structural building systems could be used to expand the warehouse and conceptual plans to upgrade exterior lighting to help increase safety and decrease the possibility of vandalism or theft.

Improving Logistics and Efficiencies

In addition to providing engineering design services for several stages of their warehouse expansion, Morrison-Maierle also analyzed the logistics and suggested increasing efficiencies in the warehouse operations. We provided recommendations regarding best practices for general warehouse storage, pallet racking, cross-docking, and loading dock safety.

Cross-docking is the process of unloading freight from an inbound load and then loading it directly into an outbound shipment with little to no storage time in-between. Implementing the cross-docking process at the Columbus facility would free up warehouse space, lessen inventory handling, and reduce delivery times to Stillwater’s other facilities.

Implementing this practice could significantly enhance Sibanye Stillwater’s efforts to support its broader goals of maximizing efficiency and better utilizing its facilities.

Discover more about our multi-disciplinary servicesRelated Projects

Round Mountain Mine Phase W

Kinross selected Morrison-Maierle to perform detailed engineering for various infrastructure and processing needs for their significant mine pit relocation and expansion.

Round Mountain Mill Flotation Expansion

Round Mountain Gold Corporation hired Morrison-Maierle to assist with the Round Mountain Mill Flotation Expansion for their existing scavenger flotation circuit.

Mill Flotation Improvements Value Engineering Study

This Value Engineering Study was drafted and transmitted to Round Mountain Gold Company which recommended changes that saved them $5,733,530 compared to the initial design.